Page 95 of 105

Re: My EK project

Posted: Sat Apr 18, 2015 1:28 pm

by Harv

Mick Jagger wrote:have got motor idling nicely now me thinks rear main rope seal is leaking

what would be the easiest solution?

Park it on a piece of cardboard

. If there ain't no oil under it, there ain't no oil in it.

Cheers,

Harv

Re: My EK project

Posted: Sat Apr 18, 2015 1:33 pm

by Devilrod

Or wedge a piece of foam between the inspection cover and sump.... It works as a temporary fix.

Re: My EK project

Posted: Sat Apr 18, 2015 1:57 pm

by Mick Jagger

Tits or Tyres as they say

was wondering if I could take the motor out flip it over and raise the crank an inch or so and try replacing it that way

if that's whats leaking,could be the sump?(wishful thinking)

Ahh the joys of working on cars

maybe I could do a skid,that might fix it?

Ive got it, tie a jar under the car with some cotton,then I can simply pour the oil back in the top after every drive

im a solutions man

Re: My EK project

Posted: Sat Apr 18, 2015 3:37 pm

by Blacky

Its been a while since it has been running hasn't it ? I would leave it a week or 2 and see if it takes up - you never know ......

Re: My EK project

Posted: Sat Apr 18, 2015 5:41 pm

by Mick Jagger

I started it yesterday for the first time but it has sat for over a year

lets hope the rope swells

swell you bastard

drove it with no brakes today

nearly hit the trampoline

clutch works

ive always hated the rear main seal and ive never got it 100% right

would be nice to know how they did them originally

will wait and see

im going to take a video and put it on the you tube

if my 11 year old will show me how

and will post a link ,I can do that

Re: My EK project

Posted: Sat Apr 18, 2015 6:00 pm

by Harv

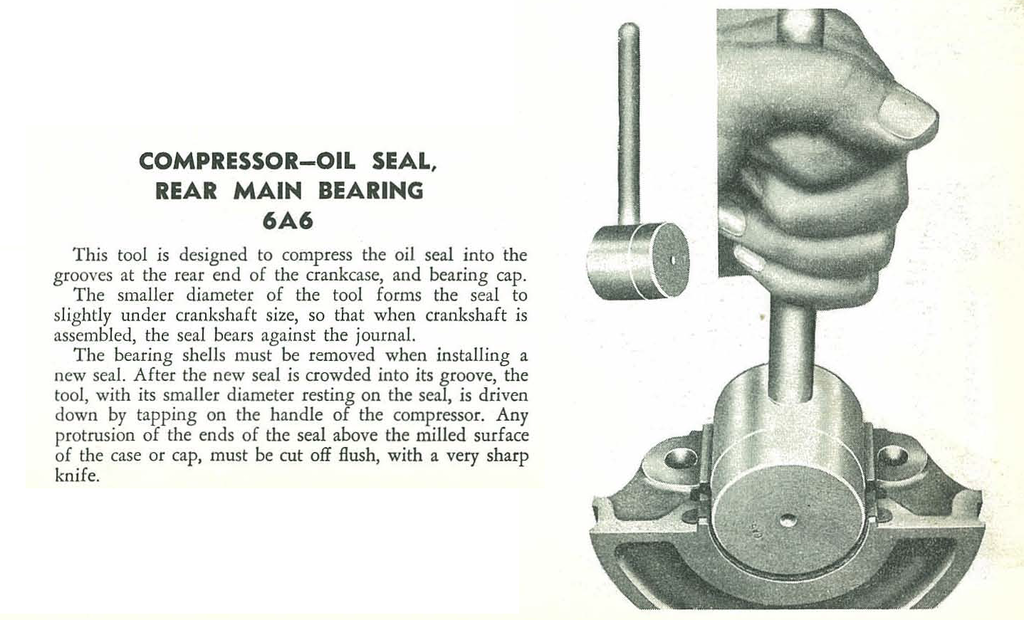

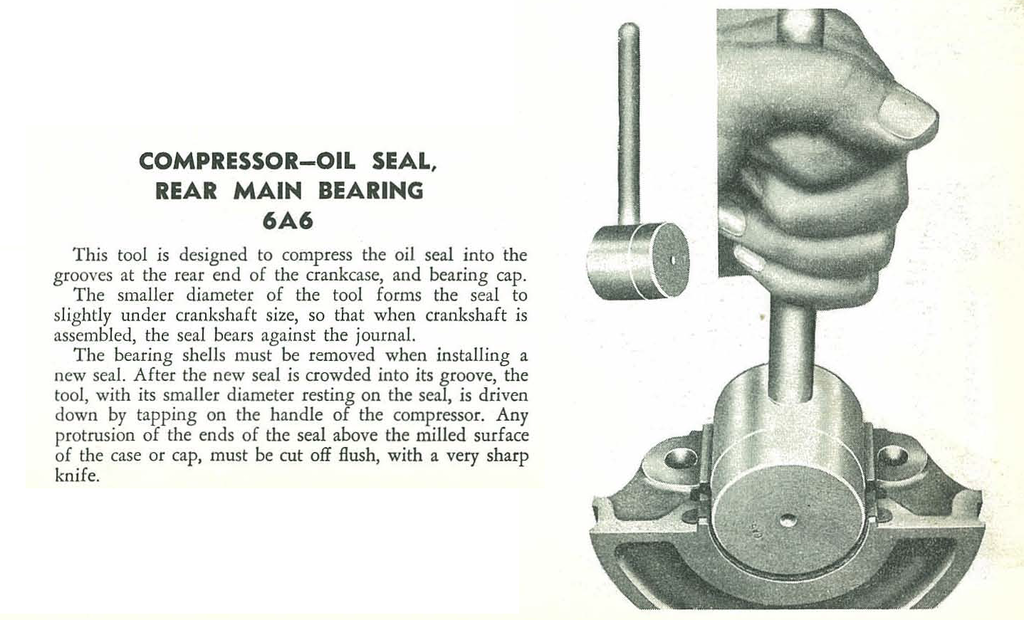

Mick Jagger wrote:ive always hated the rear main seal and ive never got it 100% right

would be nice to know how they did them originally

Like this:

Worse comes to worse, if it doesn't reseat you can always try a can of that "Liquid Intelligence" seal sweller from SuperCheap... not a big fan, but probably better than tearing it down just for a rear-main.

Cheers,

Harv

Re: My EK project

Posted: Sat Apr 18, 2015 7:55 pm

by Mick Jagger

Lesson learnt

I soaked in oil

Used the biggest socket i had

And pieces of pipe to knock the

Bastard home

Where I went wrong was leaving

To much crush

Re: My EK project

Posted: Sun Apr 19, 2015 12:18 am

by Devilrod

Mick Jagger wrote:

was wondering if I could take the motor out flip it over and raise the crank an inch or so and try replacing it that way

if that's whats leaking

Yeah you can. I did that to mine a few years back for the Sawtell Nats.

Re: My EK project

Posted: Sun Apr 19, 2015 4:12 pm

by Mick Jagger

Re: My EK project

Posted: Wed Apr 22, 2015 7:07 pm

by ben

Looks and sounds awesome MJ well done

Re: My EK project

Posted: Thu Apr 23, 2015 2:02 am

by FBeing

I agree. That's cool

Re: My EK project

Posted: Wed Apr 29, 2015 8:28 pm

by Mick Jagger

cheers big ears

im going to have to pull the motor out

to replace that darn rear seal

its a 186A block so HR in the gregorys manual its says

not the rope seal....

lets hope its raining tomorrow so I can make a start

heres the first video I made with Bronson that didn't make the cut....see those lights

https://www.youtube.com/watch?v=ouOK5tP7ECI

https://www.youtube.com/watch?v=ouOK5tP7ECI

Re: My EK project

Posted: Thu Jun 11, 2015 7:39 pm

by Mick Jagger

there are 3 types of rear main seals

If there are 3 vertical ribs running externally between the cam tunnel and the sump rail at the drivers rear of the block then there is every chance its a rope seal. i have never seen a neoprene seal with these 3 ribs.

Holden Red sixes actually had three types of rear main seals. The very early engines had a moulded rubber seal that fitted into a groove in the block THATS MY BLOCK !!!!god dam (same as rope seal). Aftermarket gasket sets for these engines contained a rope type seal and were called "conversion" sets (converting the rubber seal to rope type). Early 70's engines used a neoprene seal that fitted over a raised lip on the block. Engines from late HQ on (IIRC) had rope type rear main seals. The seal area on all 202 crankshafts (neoprene or rope) is the same diameter. The seal area on 149/186 crankshafts has a smaller diameter. The diagonal notches on a rope seal crank are to lubricate the seal and make it swell, so enabling a better seal. Don't use a rope seal crank with a neoprene seal, or vice versa. A neoprene type crank with a rope seal will make the seal run dry and cause it to spin in its groove. The grooves in a rope type crank will obviously damage a neoprene seal, however, a neoprene seal with an offset lip was once available (and may still be) for use with a rope type crank

my cars all pulled to bits again...so it looks like a rope seal goes in but the crank journals way smaller

the parts ready to be picked up

repco hung up on me!

there is only 2 .....rope or rubber ,

at the end of the day my block and caps look to run a rope seal,the crank is smooth and a lot smaller 2.6/2.42"

gee wiz I have built a few red sixes ,I love em ,my mistake

will tell part # tomorrow

Re: My EK project

Posted: Thu Jul 02, 2015 8:01 pm

by Mick Jagger

seals done ..

clutch works.

brakes are all bled all new lines,everything is new and they work .

I need to make a contraption for the hand brake cable on the gearbox crossmember

and get a speedo cable

oh and a few mod plates and rego...

I love my car

Re: My EK project

Posted: Thu Jul 02, 2015 9:33 pm

by wot179