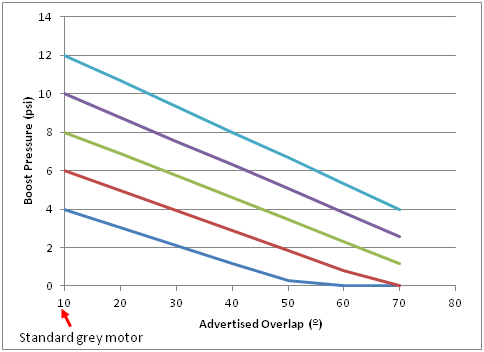

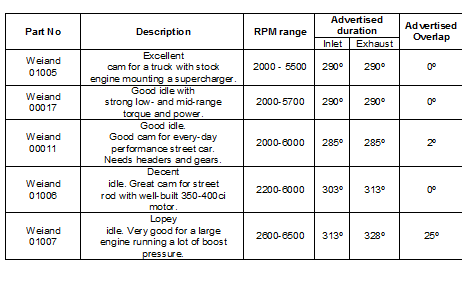

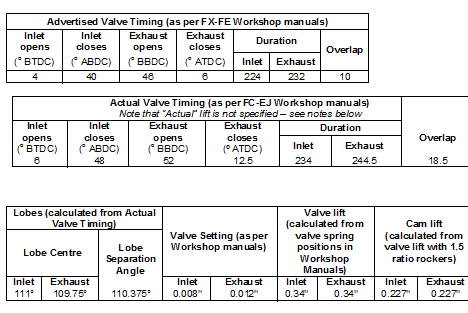

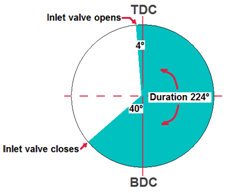

Harv wrote:How Many Carbs do I Need – the Atkins Diet for Normans.

Harv's Norman supercharger thread

Re: Harv's Norman supercharger thread

Alan

Member No.1 of the FB EK Holden Car Club of WA (Woo-hoo sweet!)

sweet!)

Member No.1 of the FB EK Holden Car Club of WA (Woo-hoo

Re: Harv's Norman supercharger thread

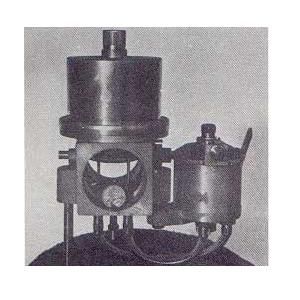

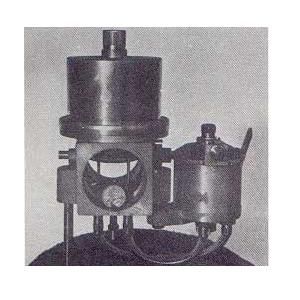

It would be sacriledge to talk SUs, and not mention the very, very large 3” SU carbs made specifically for Eldred Norman. To put this into perspective, if your typical Mini is running a pair of HS2s (or a single HS4), and your typical Norman-blown grey motor is running a pair of HS6 or a single HS8, this monster would be a HS16. The carbs are even more rare than the superchargers themselves, and are twin-needle/jet setups. The twin needles are visible in the throat of the carburettor shown below (which I have taken from Supercharge!)... along with a 20c piece for perspective.

Note the size of the float bowl on the side of the carburettor... almost the size of a billy can.

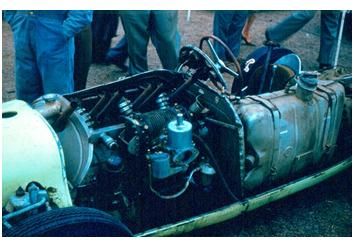

The two photos below right show the 3” Norman SU on a grey motor located in one of the FE/FC Holden forum members vehicles.

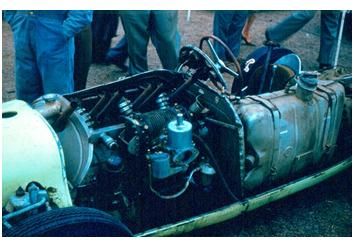

The image below shows Keith Rilstone's 2.3L 280-300bhp ex-Eldred Norman Zephyr special. The photo was taken at the Mallala Race Circuit South Australia. The car was previously known as the the Norholfordor - because it was built from Holden, &*#@ and Tempo Matador parts, and then the Zephyr Eclipse (from the Adelaide &*#@ dealer, Eclipse Motors).

Red motor anyone?

Cheers,

Harv (appreciator of monster SUs)

Note the size of the float bowl on the side of the carburettor... almost the size of a billy can.

The two photos below right show the 3” Norman SU on a grey motor located in one of the FE/FC Holden forum members vehicles.

The image below shows Keith Rilstone's 2.3L 280-300bhp ex-Eldred Norman Zephyr special. The photo was taken at the Mallala Race Circuit South Australia. The car was previously known as the the Norholfordor - because it was built from Holden, &*#@ and Tempo Matador parts, and then the Zephyr Eclipse (from the Adelaide &*#@ dealer, Eclipse Motors).

Red motor anyone?

Cheers,

Harv (appreciator of monster SUs)

327 Chev EK wagon, original EK ute for Number 1 Daughter, an FB sedan meth monster project and a BB/MD grey motored FED.

Re: Harv's Norman supercharger thread

In this post, I will cover some of the preparations required for the casing liner. I know this is jumping around a bit from the last post on SUs, but that’s the price you pay for me doing this as a string of forum posts (if I did it as a Guide, the sequencing is more logical with less jumping around… but would take me longer to get the finished product to you). Al - this post also helps with your concern that I'm doing too much theory and not enough overhauling

.

.

Norman superchargers have an alloy casing with a steel liner. Later Norman superchargers (and potentially also the earlier ones) had the casing liner surface hardened by Tuff-Trided. Tuff-Triding (also known as salt bath ferritic nitrocarburizing) is a steel hardening process. It works by adding extra nitrogen and carbon into the iron. Tuff-Triding improves scuffing, fatigue and corrosion properties by producing a layer of hardened material (iron nitride) of 10-20µm (0.0003-0.0006”) thick, with a surface hardness of 800-1,500HV (Vickers scale – mild steel is typically 230HV, whilst tungsten carbide is 2,500 and diamond is 10,000HV). The metal under this thin, hard layer is also changed by the process.

Over time, the Tuff-Tride surface can be removed (by wear, corrosion or poor machining). To check if the Tuff-Tride treated surface is still present, copper sulphate can be used. If the hard iron nitride surface is still present, the copper sulphate won’t react. If the Tuff-Triding has been removed however the copper sulphate can get at the iron and will react (for the science geeks, the iron will reduce the copper, leading to the copper plating out: Fe + CuSO4 → FeSO4 + Cu). To do the testing:

a) I bought some copper sulphate. This is available as “bluestone” from nurseries – it is a pretty common algaecide used to control weeds in paths and algae in water.

b) I sat the supercharger barrel horizontal, and cleaned the test area with some thinners - there must be no traces of oil on the surface to be tested.

c) I made up a 5 - 10% solution of copper sulphate dissolved in distilled water. This is the blue liquid you can see in the photos sitting in an upturned grey spray paint tin lid.

d) I applied a dab of the solution to the surface being inspected, leaving in place for 30 - 40 seconds.

f) If there is discoloration (i.e. the solution changes from a light blue colour to transparent and the steel surface takes on a copper/rust color) after this time, the Tuff-Tride treatment has been removed. If the solution stays a blue colour, the Tuff-triding is still present.

g) I washed down the steel surface immediately with plenty of water, as copper sulphate is corrosive. I then re-oiled the surface to protect against rust.

When I did the testing, I found that the Tuff-Triding was still present on my small Norman, my large Norman and Gary’s large Norman. However, the Tuff-Triding had been removed from the surface of Gary’s Type 65 Norman. You can see in the photo where the copper from the copper sulphate solution has plated out onto the liner surface (don’t panic, this copper does not stick to the casing, and wipes off easily).

Later machining of the Type 65 shows that although the Tuff-Trising had been removed from the surface, it still had a thin hard layer underneath (this is the changes in the parent metal that also come with Tuff-Triding). Note that so far I haven’t tested my water cooled Norman or my clutched Norman as I ran out of time – I wanted the casings cleaned and checked before testing and machining.

The reason for the above testing is to work out whether or not to hone the casings. Honing is required to clean up any small surface scratches in the casing, and more importantly to leave behind a cross-hatch pattern. The cross-hatching provides a surface that will retain an oil film, which we need to lubricate the vanes as they whizz around (retaining an oil film is exactly the same reason that engine cylinders are honed). For sliding vane superchargers that are not case-hardened (for example Judson superchargers) honing is undertaken at all overhauls (Sorry Al - your'e gunna hafta hone yours ). However, there is a bit of a trade-off here if the surface is Tuff-Trided, like the Normans. Honing will generally remove 0.003-0.005” of material (… or more if heavy handed). Bearing in mind that the original Tuff-Triding is probably only 0.0003-0.0006” thick (maybe 0.0015” if it is old, old Tuff-Triding), there is a pretty good chance that honing will remove the case hardening. This will reduce the life of the supercharger barrel. It is of course possible to press out the barrel liner, have it case hardened again and refitted… though this is a pretty substantive task with good risk of damage and expensive. It really becomes a balance between good oiling (and hence longer vane life) against reduced casing life. For what it’s worth (and after having had a good long discussion with a very experienced machine shop and a Tuff-Triding shop), I take the following view:

). However, there is a bit of a trade-off here if the surface is Tuff-Trided, like the Normans. Honing will generally remove 0.003-0.005” of material (… or more if heavy handed). Bearing in mind that the original Tuff-Triding is probably only 0.0003-0.0006” thick (maybe 0.0015” if it is old, old Tuff-Triding), there is a pretty good chance that honing will remove the case hardening. This will reduce the life of the supercharger barrel. It is of course possible to press out the barrel liner, have it case hardened again and refitted… though this is a pretty substantive task with good risk of damage and expensive. It really becomes a balance between good oiling (and hence longer vane life) against reduced casing life. For what it’s worth (and after having had a good long discussion with a very experienced machine shop and a Tuff-Triding shop), I take the following view:

a) If the case hardening is not present, hone the casing.

b) If the case hardening is present, but the casing shows significant corrosion or heavy scratches, hone the casing.

c) If the case hardening is present, but the casing is otherwise OK, do not hone the liner.

Note that an alternative to honing (say to remove very limited corrosion) is to polish internally by either lapping with emery cloth (grade 360 or finer), or blasting with glass beads (size 40-70μm in diameter, with pressure less than 4 bar). Polishing in this manner is supported by the Tuff-Tride process owner ( Reference: TUFFTRIDE®-/QPQ®-PROCESS Technical Information, Dr. Joachim Boßlet / Michael Kreutz, Durferrit GmbH (http://www.durferrit.com).), but can however partly reduce the corrosion resistance of the liner.

Using the above logic, I took the decision to hone my small Norman (case hardening present, but casing showing significant corrosion) and Gary’s Type 65 Norman (case hardening worn off), but did not hone Gary’s large Norman or my large Norman (case hardening present and casings generally in good condition). The honing was completed by Duncan Foster Engineering, one of the few places around that have hones for the large diameter supercharger barrels (many engine reconditioners can only hone smaller engine-cylinder type diameters). The photos attached show the nice cross-hatching obtained.

Cheers,

Harv (deputy apprentice Norman supercharger apprentice).

Norman superchargers have an alloy casing with a steel liner. Later Norman superchargers (and potentially also the earlier ones) had the casing liner surface hardened by Tuff-Trided. Tuff-Triding (also known as salt bath ferritic nitrocarburizing) is a steel hardening process. It works by adding extra nitrogen and carbon into the iron. Tuff-Triding improves scuffing, fatigue and corrosion properties by producing a layer of hardened material (iron nitride) of 10-20µm (0.0003-0.0006”) thick, with a surface hardness of 800-1,500HV (Vickers scale – mild steel is typically 230HV, whilst tungsten carbide is 2,500 and diamond is 10,000HV). The metal under this thin, hard layer is also changed by the process.

Over time, the Tuff-Tride surface can be removed (by wear, corrosion or poor machining). To check if the Tuff-Tride treated surface is still present, copper sulphate can be used. If the hard iron nitride surface is still present, the copper sulphate won’t react. If the Tuff-Triding has been removed however the copper sulphate can get at the iron and will react (for the science geeks, the iron will reduce the copper, leading to the copper plating out: Fe + CuSO4 → FeSO4 + Cu). To do the testing:

a) I bought some copper sulphate. This is available as “bluestone” from nurseries – it is a pretty common algaecide used to control weeds in paths and algae in water.

b) I sat the supercharger barrel horizontal, and cleaned the test area with some thinners - there must be no traces of oil on the surface to be tested.

c) I made up a 5 - 10% solution of copper sulphate dissolved in distilled water. This is the blue liquid you can see in the photos sitting in an upturned grey spray paint tin lid.

d) I applied a dab of the solution to the surface being inspected, leaving in place for 30 - 40 seconds.

f) If there is discoloration (i.e. the solution changes from a light blue colour to transparent and the steel surface takes on a copper/rust color) after this time, the Tuff-Tride treatment has been removed. If the solution stays a blue colour, the Tuff-triding is still present.

g) I washed down the steel surface immediately with plenty of water, as copper sulphate is corrosive. I then re-oiled the surface to protect against rust.

When I did the testing, I found that the Tuff-Triding was still present on my small Norman, my large Norman and Gary’s large Norman. However, the Tuff-Triding had been removed from the surface of Gary’s Type 65 Norman. You can see in the photo where the copper from the copper sulphate solution has plated out onto the liner surface (don’t panic, this copper does not stick to the casing, and wipes off easily).

Later machining of the Type 65 shows that although the Tuff-Trising had been removed from the surface, it still had a thin hard layer underneath (this is the changes in the parent metal that also come with Tuff-Triding). Note that so far I haven’t tested my water cooled Norman or my clutched Norman as I ran out of time – I wanted the casings cleaned and checked before testing and machining.

The reason for the above testing is to work out whether or not to hone the casings. Honing is required to clean up any small surface scratches in the casing, and more importantly to leave behind a cross-hatch pattern. The cross-hatching provides a surface that will retain an oil film, which we need to lubricate the vanes as they whizz around (retaining an oil film is exactly the same reason that engine cylinders are honed). For sliding vane superchargers that are not case-hardened (for example Judson superchargers) honing is undertaken at all overhauls (Sorry Al - your'e gunna hafta hone yours

a) If the case hardening is not present, hone the casing.

b) If the case hardening is present, but the casing shows significant corrosion or heavy scratches, hone the casing.

c) If the case hardening is present, but the casing is otherwise OK, do not hone the liner.

Note that an alternative to honing (say to remove very limited corrosion) is to polish internally by either lapping with emery cloth (grade 360 or finer), or blasting with glass beads (size 40-70μm in diameter, with pressure less than 4 bar). Polishing in this manner is supported by the Tuff-Tride process owner ( Reference: TUFFTRIDE®-/QPQ®-PROCESS Technical Information, Dr. Joachim Boßlet / Michael Kreutz, Durferrit GmbH (http://www.durferrit.com).), but can however partly reduce the corrosion resistance of the liner.

Using the above logic, I took the decision to hone my small Norman (case hardening present, but casing showing significant corrosion) and Gary’s Type 65 Norman (case hardening worn off), but did not hone Gary’s large Norman or my large Norman (case hardening present and casings generally in good condition). The honing was completed by Duncan Foster Engineering, one of the few places around that have hones for the large diameter supercharger barrels (many engine reconditioners can only hone smaller engine-cylinder type diameters). The photos attached show the nice cross-hatching obtained.

Cheers,

Harv (deputy apprentice Norman supercharger apprentice).

327 Chev EK wagon, original EK ute for Number 1 Daughter, an FB sedan meth monster project and a BB/MD grey motored FED.

Re: Harv's Norman supercharger thread

Already doneHarv wrote:For sliding vane superchargers that are not case-hardened (for example Judson superchargers) honing is undertaken at all overhauls (Sorry Al - your'e gunna hafta hone yours).

Like you say, took a while to find an engine reconditioners with a power-hone. In the end I went to Favazzo's. Their power-hone guru, Murray, is about 100 years old and took a keen interest in my supercharger. I think he's one of these guys that just keeps working because he enjoys the environment. Cool guy. Anyway, Murray was even kind enough to make up a mount to hold my barrel in the hone. He did an awesome job and charged me $80. I tried to give him more but he wouldn't have it. I left feeling glad that the barrel was a bit rusty, otherwise I'd never have met Murray.

Never thought of case-hardening

Alan

Member No.1 of the FB EK Holden Car Club of WA (Woo-hoo sweet!)

sweet!)

Member No.1 of the FB EK Holden Car Club of WA (Woo-hoo

Re: Harv's Norman supercharger thread

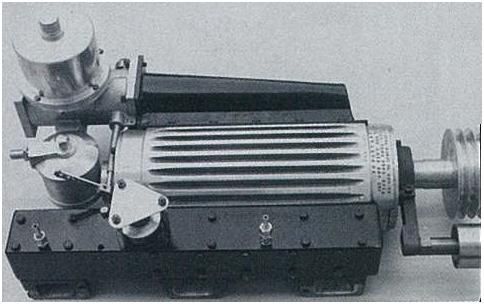

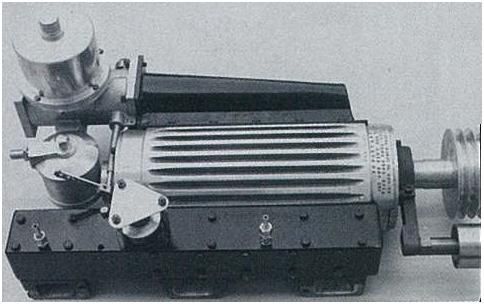

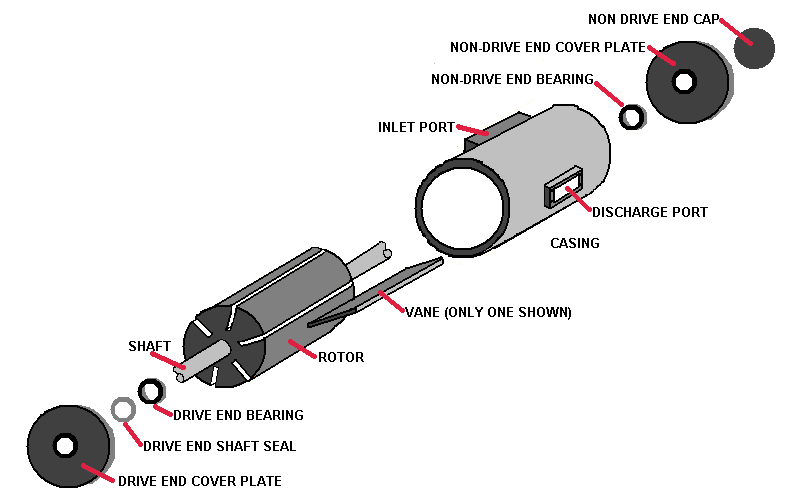

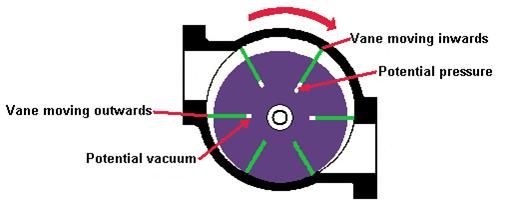

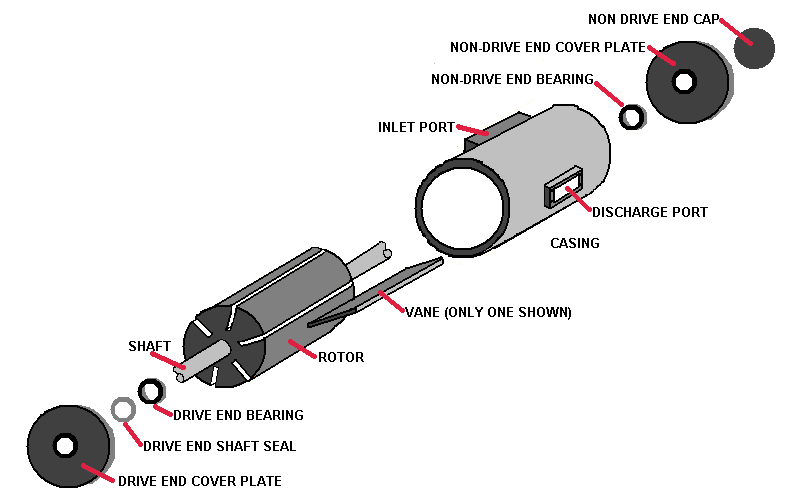

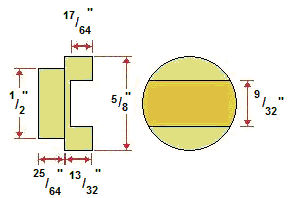

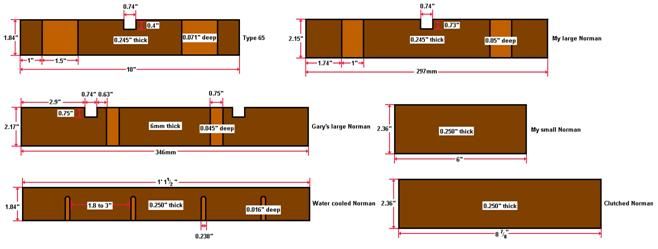

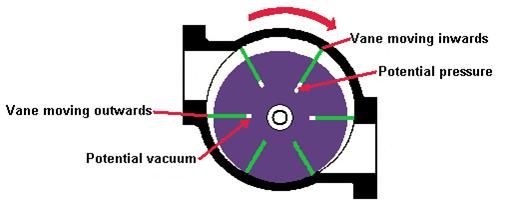

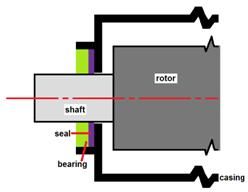

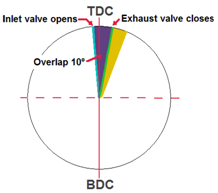

For this post, we will take a look at the rotors that are used in Norman superchargers. Now that we are starting to look at internals, the sketch below may help to better visualize the way that the Normans are put together:

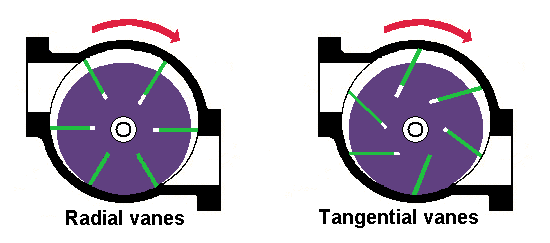

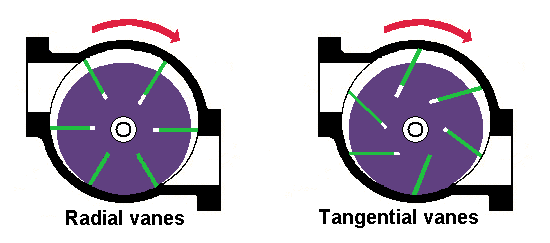

The shaft of a sliding vane supercharger supports the rotor, which may be made from steel or from aluminum alloy. Whilst Norman superchargers have solid rotors, some supercharger rotors are made from hollow extruded sections in order to minimize weight. The rotor may be mounted centrally within the casing, or may be mounted eccentrically (Norman superchargers are eccentric, whilst the vanes in many air tools are mounted centrally). The rotor contains a number of slots (two, four, six or more), which may be radial or tangential (Norman superchargers are tangential), whilst air tools for example are often radial).

The slots carry the rotor vanes, which are free to slide in and out of the slots. Centripetal force causes the vanes to be held outwards against the walls of the casing, forming a seal.

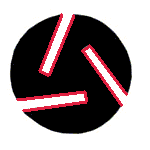

A significant change is noticeable between Eldred’s earlier rotors and the later ones produced by Mike Norman. The earlier rotors are steel, drilled through with the steel drive shaft welded in. These rotors are four-vane units as per the left-hand image below. The later model rotors are machined from a light alloy bar before being fitted with a steel driveshaft. These rotors are three-vane units, as per the right-hand image below.

Additionally, the later model rotors have Tuff-Trided sheet steel inserts riveted into the vane slots (as per the red lines on the image below) to decrease rotor slot wear. The inserts can be seen riveted into the vane slots in the left hand corner of the photo below.

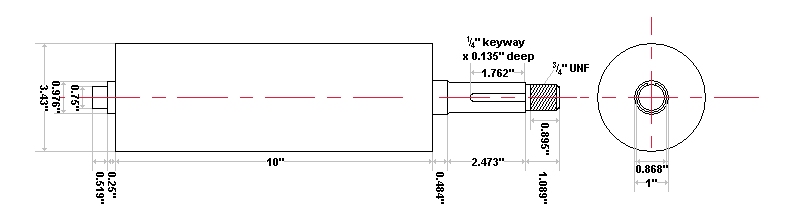

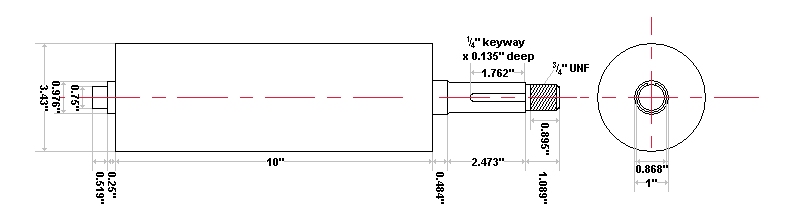

A typical rotor (this is Gary’s Type 65) is shown below:

At some stage I'll sketch up the rest of the rotors and post them here (time is not on my side at the moment ).

).

The rotors have a number of common features:

• Lands at either end of the shaft to support both the drive-end and non-drive end bearings,

• A land at the drive end to support the drive-end seal,

• A keyway milled into the drive-end of the shaft to provide axial locking of the drive pulley, and

• A threaded section at the end of the shaft to mount the pulley retaining nut.

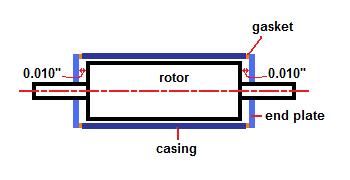

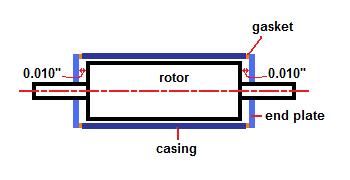

Note that Norman superchargers do not have thrust bearings. Any thrust loading is transferred through to the drive-end and non-drive end bearings. To minimize thrust (and maintain adequate clearance) care needs to be taken in the selection of the gaskets between the main casing and end plates. Whilst no guidance exists for the Normans, typical Judson supercharger practice is to select the gasket thickness such that 0.010” float exists between the rotor and end case at each end.

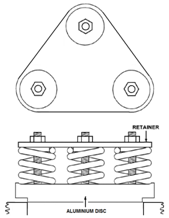

As the rotor spins, the vanes are forced against the casing wall by centripetal force. The eccentric rotor position means that the vanes slide in and out as the rotor spins. When the vanes are travelling into the rotor, they develop some inertia, and want to keep travelling inwards. As the rotor keeps spinning to the point that the vanes should come out again, the vanes will have a tendency to stay in the rotor slot and hence lift off the casing wall slightly. This tends to happen after the discharge port is passed (and before the inlet port is reached) and hence is probably not much of an efficiency loss. However, the lift-off adds to the supercharger nose, and the repeated banging of the vanes is probably not good for their longevity. To combat the vane lift-off, the latter alloy rotors are fitted with vane springs. The springs are fitted into holes (pockets) drilled into each rotor slot. A plastic bush is fitted between the compression spring and the vane prior to the vane being inserted into the rotor. The springs provide an outwards force on the vane, similar to the centripetal force that normally pushed the vanes out.

The spring operation will be periodic – typically the vehicle will run for 30-60 minutes at a time, with rest periods in between when the car is shut down. During rest periods the springs will be at ambient temperature, though during service will increase. The springs will typically cycle at around crankshaft speed – say a maximum of 4500 cycles per minute, though probably on average 2500 cycles per minute. The springs will operate in an environment of a gasoline/air/oil vapour, with some humidity. Whilst no free water is likely, water content may approach saturation. It is a fair assumption that the springs will only be checked when the supercharger is overhauled – if we used Eldred’s guidance of servicing every 20,000 miles, then the springs are likely to complete 65 million cycles before seeing daylight again. All of this adds up to a very harsh operating environment for a spring to operate in – bear in mind that typical commercially available springs (other than specialties like valve springs) are normally only factory fatigue tested to 10,000 cycles. Most commercial springs are also good for only around ¾” of deflection, whilst the Norman springs deflect around 1½”. The original springs have a reputation for failing in service, and are often removed by enthusiasts to prevent failure. If the springs do fail in service, most (if not all) the shards of spring are likely to be held in place by the plastic bushes, largely preventing them from entering the engine. However, there is a good chance of the hardened steel spring shards chewing out the soft alloy rotor pocket. The image above shows an original spring and bush, together with one that had failed in service.

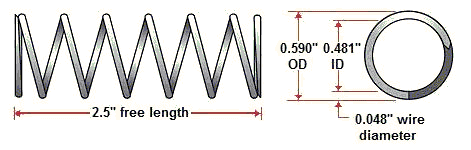

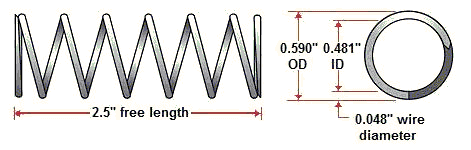

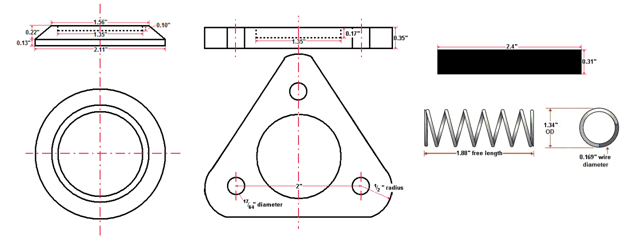

The original springs have dimensions as shown in the image below, and a stiffness of approximately 3.7lb/inch.

For those seeking replacement springs, Century Spring Corporation part number 12063 are very similar… though resist the temptation to use them, as discussion with Century show that the fatigue life is not likely to be suitable due to the spring steel material used (the springs are also a trifle heavy at 5.1lb/inch). Custom springs are likely to be required for long-term use. A suitable supplier for the springs is Boynes Springs (6 Sarich Court Osborne Park, Western Australia 6017 Australia, Telephone: (08) 94465666, Facsimile: (08) 92441465, Email: info@boynessprings.com.au, Internet: http://www.boynessprings.com.au), who can make the required springs. If anyone wants some springs for their Norman, give me a yell (I had a few spare ones made up ).

).

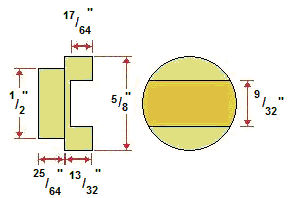

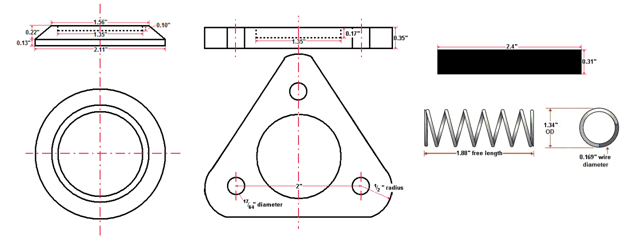

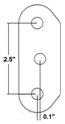

The bushes noted above have the following dimensions:

Note that the bushes could be readily made from either nylon or PTFE (Teflon). Care needs to be taken when using nylon, as some grades of nylon (for example Nylon 6.11) have melting temperatures as low as 190ºC. Whilst the supercharger will not operate that hot (without pinging its head off), the localized friction of the bushes running in their pockets will certainly increase temperature. Because of this, PTFE (with a melting temperature of 327ºC) is a better choice. As a side note, I have a 1' length of teflon bar at home that I need to machine down into the above bushes (some for me and some spares). If there are any machinists out there who would undertake this for me, I'd love to hear from you (my lathe skills are pretty poor ).

).

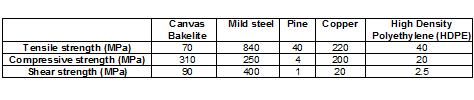

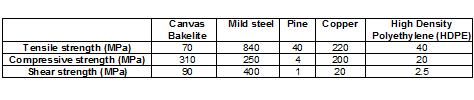

The vanes used in Norman superchargers are made from Bakelite, also known as polyoxybenzylmethylenglycolanhydride. Bakelite is an early plastic, and is thermosetting (i.e. when you heat it up, it will char rather than melting). Bakelite saw quite some use in the automotive industry, for example in the manufacture of rotor buttons and distributor caps for early Holdens. The Bakelite used in Norman supercharger rotors is sometimes referred to as phenolic sheet or canvas Bakelite. This is made by applying heat and pressure to layers of cotton fabric impregnated with Bakelite resin to make a laminate. Bakelite in this form has good mechanical properties (as per the table below), is strong, rigid, shows negligible creep or cold flow under load whilst still being light (about 20-25% the weight of steel).

Canvas Bakelite is suitable for a continuous operating temperature of around 120ºC (130ºC peak).

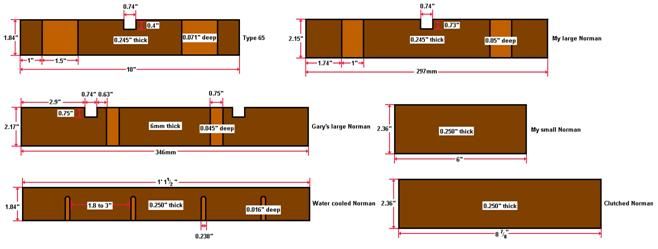

Dimensions for some of the different Norman supercharger vanes are given below:

In the above diagrams, the darker sections represent the main portion of the vanes, whilst the lighter portions represent grooves that are milled into the trailing edge of the vanes. Note that some of the grooves are milled all the way across the face of the vane, whilst others are milled only partially across the face. The grooves are likely to be used to assist the vanes in being able to move in and out of the rotor. The vanes should be a “flop” fit, though may experience some changes in dimensions due to moisture, fuel properties or dirt. If the vanes become a tight fit, the oily environment they operate in may allow them to form a seal with the rotor. In this case, the vanes will draw a vacuum at the vane root as they try to slide out, or will build pressure at the vane root as they slide back in. The slots allow the vane root to equalize pressure, allowing the vanes to slide freely. The slots also allow some flow of air/fuel/oil around the vane, helping lubrication.

Note that some vanes also have one or two notches cut into them. The notches correspond to the vane springs, giving the plastic bushes a location to bear on the vanes. Interestingly, the Type 65 rotor in Gary’s Norman had a notch despite the rotors not having pockets for springs… perhaps an over-enthusiastic vane replacement in the past.

A suitable supplier for the vanes is Bearing Thermal Resources (5 Kerr Court Rowville, Victoria 3178 Australia, Telephone: (03) 97642009, Facsimile: (03) 97641009, Email: sales@btresources.com.au, Internet: http://www.btresources.com.au), who can make the required vanes.

Cheers,

Harv (deputy apprentice Norman supercharger fiddler).

The shaft of a sliding vane supercharger supports the rotor, which may be made from steel or from aluminum alloy. Whilst Norman superchargers have solid rotors, some supercharger rotors are made from hollow extruded sections in order to minimize weight. The rotor may be mounted centrally within the casing, or may be mounted eccentrically (Norman superchargers are eccentric, whilst the vanes in many air tools are mounted centrally). The rotor contains a number of slots (two, four, six or more), which may be radial or tangential (Norman superchargers are tangential), whilst air tools for example are often radial).

The slots carry the rotor vanes, which are free to slide in and out of the slots. Centripetal force causes the vanes to be held outwards against the walls of the casing, forming a seal.

A significant change is noticeable between Eldred’s earlier rotors and the later ones produced by Mike Norman. The earlier rotors are steel, drilled through with the steel drive shaft welded in. These rotors are four-vane units as per the left-hand image below. The later model rotors are machined from a light alloy bar before being fitted with a steel driveshaft. These rotors are three-vane units, as per the right-hand image below.

Additionally, the later model rotors have Tuff-Trided sheet steel inserts riveted into the vane slots (as per the red lines on the image below) to decrease rotor slot wear. The inserts can be seen riveted into the vane slots in the left hand corner of the photo below.

A typical rotor (this is Gary’s Type 65) is shown below:

At some stage I'll sketch up the rest of the rotors and post them here (time is not on my side at the moment

The rotors have a number of common features:

• Lands at either end of the shaft to support both the drive-end and non-drive end bearings,

• A land at the drive end to support the drive-end seal,

• A keyway milled into the drive-end of the shaft to provide axial locking of the drive pulley, and

• A threaded section at the end of the shaft to mount the pulley retaining nut.

Note that Norman superchargers do not have thrust bearings. Any thrust loading is transferred through to the drive-end and non-drive end bearings. To minimize thrust (and maintain adequate clearance) care needs to be taken in the selection of the gaskets between the main casing and end plates. Whilst no guidance exists for the Normans, typical Judson supercharger practice is to select the gasket thickness such that 0.010” float exists between the rotor and end case at each end.

As the rotor spins, the vanes are forced against the casing wall by centripetal force. The eccentric rotor position means that the vanes slide in and out as the rotor spins. When the vanes are travelling into the rotor, they develop some inertia, and want to keep travelling inwards. As the rotor keeps spinning to the point that the vanes should come out again, the vanes will have a tendency to stay in the rotor slot and hence lift off the casing wall slightly. This tends to happen after the discharge port is passed (and before the inlet port is reached) and hence is probably not much of an efficiency loss. However, the lift-off adds to the supercharger nose, and the repeated banging of the vanes is probably not good for their longevity. To combat the vane lift-off, the latter alloy rotors are fitted with vane springs. The springs are fitted into holes (pockets) drilled into each rotor slot. A plastic bush is fitted between the compression spring and the vane prior to the vane being inserted into the rotor. The springs provide an outwards force on the vane, similar to the centripetal force that normally pushed the vanes out.

The spring operation will be periodic – typically the vehicle will run for 30-60 minutes at a time, with rest periods in between when the car is shut down. During rest periods the springs will be at ambient temperature, though during service will increase. The springs will typically cycle at around crankshaft speed – say a maximum of 4500 cycles per minute, though probably on average 2500 cycles per minute. The springs will operate in an environment of a gasoline/air/oil vapour, with some humidity. Whilst no free water is likely, water content may approach saturation. It is a fair assumption that the springs will only be checked when the supercharger is overhauled – if we used Eldred’s guidance of servicing every 20,000 miles, then the springs are likely to complete 65 million cycles before seeing daylight again. All of this adds up to a very harsh operating environment for a spring to operate in – bear in mind that typical commercially available springs (other than specialties like valve springs) are normally only factory fatigue tested to 10,000 cycles. Most commercial springs are also good for only around ¾” of deflection, whilst the Norman springs deflect around 1½”. The original springs have a reputation for failing in service, and are often removed by enthusiasts to prevent failure. If the springs do fail in service, most (if not all) the shards of spring are likely to be held in place by the plastic bushes, largely preventing them from entering the engine. However, there is a good chance of the hardened steel spring shards chewing out the soft alloy rotor pocket. The image above shows an original spring and bush, together with one that had failed in service.

The original springs have dimensions as shown in the image below, and a stiffness of approximately 3.7lb/inch.

For those seeking replacement springs, Century Spring Corporation part number 12063 are very similar… though resist the temptation to use them, as discussion with Century show that the fatigue life is not likely to be suitable due to the spring steel material used (the springs are also a trifle heavy at 5.1lb/inch). Custom springs are likely to be required for long-term use. A suitable supplier for the springs is Boynes Springs (6 Sarich Court Osborne Park, Western Australia 6017 Australia, Telephone: (08) 94465666, Facsimile: (08) 92441465, Email: info@boynessprings.com.au, Internet: http://www.boynessprings.com.au), who can make the required springs. If anyone wants some springs for their Norman, give me a yell (I had a few spare ones made up

The bushes noted above have the following dimensions:

Note that the bushes could be readily made from either nylon or PTFE (Teflon). Care needs to be taken when using nylon, as some grades of nylon (for example Nylon 6.11) have melting temperatures as low as 190ºC. Whilst the supercharger will not operate that hot (without pinging its head off), the localized friction of the bushes running in their pockets will certainly increase temperature. Because of this, PTFE (with a melting temperature of 327ºC) is a better choice. As a side note, I have a 1' length of teflon bar at home that I need to machine down into the above bushes (some for me and some spares). If there are any machinists out there who would undertake this for me, I'd love to hear from you (my lathe skills are pretty poor

The vanes used in Norman superchargers are made from Bakelite, also known as polyoxybenzylmethylenglycolanhydride. Bakelite is an early plastic, and is thermosetting (i.e. when you heat it up, it will char rather than melting). Bakelite saw quite some use in the automotive industry, for example in the manufacture of rotor buttons and distributor caps for early Holdens. The Bakelite used in Norman supercharger rotors is sometimes referred to as phenolic sheet or canvas Bakelite. This is made by applying heat and pressure to layers of cotton fabric impregnated with Bakelite resin to make a laminate. Bakelite in this form has good mechanical properties (as per the table below), is strong, rigid, shows negligible creep or cold flow under load whilst still being light (about 20-25% the weight of steel).

Canvas Bakelite is suitable for a continuous operating temperature of around 120ºC (130ºC peak).

Dimensions for some of the different Norman supercharger vanes are given below:

In the above diagrams, the darker sections represent the main portion of the vanes, whilst the lighter portions represent grooves that are milled into the trailing edge of the vanes. Note that some of the grooves are milled all the way across the face of the vane, whilst others are milled only partially across the face. The grooves are likely to be used to assist the vanes in being able to move in and out of the rotor. The vanes should be a “flop” fit, though may experience some changes in dimensions due to moisture, fuel properties or dirt. If the vanes become a tight fit, the oily environment they operate in may allow them to form a seal with the rotor. In this case, the vanes will draw a vacuum at the vane root as they try to slide out, or will build pressure at the vane root as they slide back in. The slots allow the vane root to equalize pressure, allowing the vanes to slide freely. The slots also allow some flow of air/fuel/oil around the vane, helping lubrication.

Note that some vanes also have one or two notches cut into them. The notches correspond to the vane springs, giving the plastic bushes a location to bear on the vanes. Interestingly, the Type 65 rotor in Gary’s Norman had a notch despite the rotors not having pockets for springs… perhaps an over-enthusiastic vane replacement in the past.

A suitable supplier for the vanes is Bearing Thermal Resources (5 Kerr Court Rowville, Victoria 3178 Australia, Telephone: (03) 97642009, Facsimile: (03) 97641009, Email: sales@btresources.com.au, Internet: http://www.btresources.com.au), who can make the required vanes.

Cheers,

Harv (deputy apprentice Norman supercharger fiddler).

327 Chev EK wagon, original EK ute for Number 1 Daughter, an FB sedan meth monster project and a BB/MD grey motored FED.

Re: Harv's Norman supercharger thread

For this post we will take a look at the bearings and seals used in the Normans.

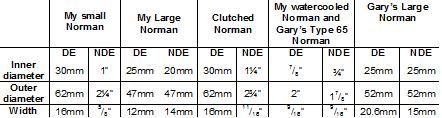

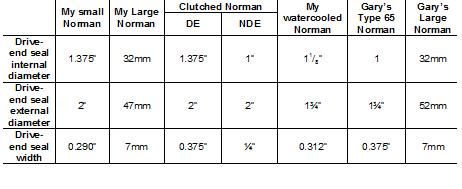

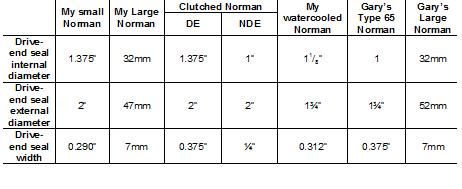

Norman superchargers typically have two bearings. The drive-end of the machine is fitted with a single row ball bearing, whilst the non-drive end is fitted with a roller bearing. Dimensions of the bearings are given in the table below:

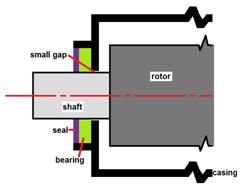

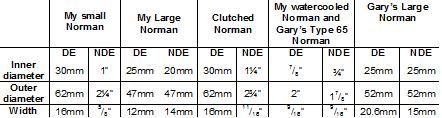

With respect to bearing lubrication, three different types of bearing arrangement are evident. In the first configuration, there is a very small gap between the casing and the rotor. This can be seen in the image below. The small gap will largely prevent the air/fuel/oil mixture (passing through the supercharger) from passing over the bearing. This means that the bearing cannot be effectively lubricated by the oil. If the bearing is of the sealed type, then no lubrication issue exists as the factory grease will provide lubrication. However, if the bearing is an open type then lubrication will be very poor, and will rely heavily on the grease packing installed during overhaul.

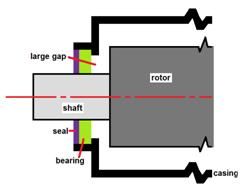

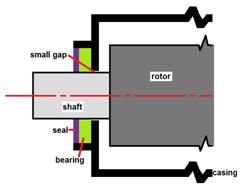

In the second type of configuration, the casing is more open, with a large gap between the casing and rotor. This can be seen in the image below. In this case the air/fuel mixture will have more contact with the bearing, and may provide some lubrication. Note however that the bearing is not oil immersed, and there is no real flow across the bearing face as one end of the bearing is blanked by the seal. The lubrication of the bearing will be very limited, and again grease packing during overhaul is recommended.

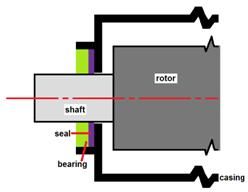

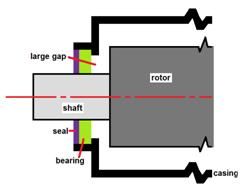

In the third configuration, the seal is observed to be installed inboard of the bearing, as per the image below. In this case the air/fuel/oil mixture provides no lubrication to the bearing. However, I have only seen this undertaken with sealed bearings, were lubrication is not required.

In choosing a suitable grease, care must be taken to choose an appropriate grade. For overhauling Norman superchargers I would recommend a grease such as Shell Gadus S3 T100. This grease:

a) is suitable for roller and ball bearings (pretty damn important given that is what it is going onto… some greases used for king pin and chassis greasing will not be suitable),

b) is good for 160ºC (a high temperature range is important particularly if no water injection is used),

c) can handle higher bearing speeds,

d) is water tolerant (important if we are using water injection upstream of the supercharger), and

e) has a long service life (important as Norman superchargers are generally not fitted with grease nipples).

Seals are used in the Norman supercharger for two purposes. Firstly (and more obviously), the seals are to close the gap between the rotating shaft and the static casing to keep the boost pressure within the supercharger. In this case a poor seal means loss of boost pressure, and also a leak of (explosive!) air/fuel mixture into the engine bay. The second reason for the use of seals is more subtle. Under low load conditions (low speed), the supercharger and inlet manifold can come under vacuum, just like a normal (naturally aspirated) engine. In these conditions, a poor seal can lead to air ingress and unstable fuel/air mixtures.

The drive-end seal of the Norman superchargers are twin lip seals with a garter spring. Dimensions of the seals are shown in the table below:

Many of the original Norman seals were of leather and/or felt construction… somewhat hard to find now. A suitable replacement is Nitrile Butadiene Rubber (NBR), which has a maximum temperature of 125°C continuous. Whilst Viton (225°C) would be a better chose, it is a lot less commonly available. In addition to NBR’s temperature limits, NBR (like all materials) has a speed limit. Most seal manufacturers rate the speed limit using surface feet per minute (or meters per second). This is a measurement of how many surface feet meters) pass a given point at the seal lip per minute (second) in time. Since this method considers the shaft diameter in addition to speed, it is a better service indicator than RPM alone. A typical seal design in NBR material can operate up to 3,000 fpm (15 m/s) assuming all other operating parameters are reasonable. For Norman supercharger shaft diameters (1-1.4” diameter) this implies a speed limit of around 8500rpm (Timkin suggests this could be a little lower at 6500rpm for their TC seals). This speed limit should not be an issue given that most Norman superchargers will run at speeds similar to that of the crankshaft (~4500rpm maximum).

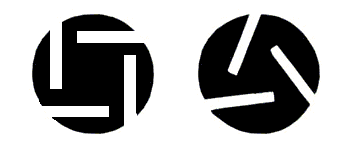

Most seals that I pulled out of the Norman superchargers are simple TC profile type seals. TC seals are typically rated for 5psi operation. Whilst 5psi is in the typical Norman supercharger range, 10psi is not out of the question. There are better seal profiles available (for example Parker’s LFN, LFE-S and MP seal profiles, as they are suitable up to 60psi). Note however that again availability may be an issue for these seal profiles – I have not yet been able to find a decent seal profile in the sizes required for Norman superchargersother than the simple TC seals. For interest, LFN, LFE-S, MP and TC seal profiles are shown (from left to right) in the image above.

Cheers,

Harv (deputy apprentice Norman supercharger fiddler)

Norman superchargers typically have two bearings. The drive-end of the machine is fitted with a single row ball bearing, whilst the non-drive end is fitted with a roller bearing. Dimensions of the bearings are given in the table below:

With respect to bearing lubrication, three different types of bearing arrangement are evident. In the first configuration, there is a very small gap between the casing and the rotor. This can be seen in the image below. The small gap will largely prevent the air/fuel/oil mixture (passing through the supercharger) from passing over the bearing. This means that the bearing cannot be effectively lubricated by the oil. If the bearing is of the sealed type, then no lubrication issue exists as the factory grease will provide lubrication. However, if the bearing is an open type then lubrication will be very poor, and will rely heavily on the grease packing installed during overhaul.

In the second type of configuration, the casing is more open, with a large gap between the casing and rotor. This can be seen in the image below. In this case the air/fuel mixture will have more contact with the bearing, and may provide some lubrication. Note however that the bearing is not oil immersed, and there is no real flow across the bearing face as one end of the bearing is blanked by the seal. The lubrication of the bearing will be very limited, and again grease packing during overhaul is recommended.

In the third configuration, the seal is observed to be installed inboard of the bearing, as per the image below. In this case the air/fuel/oil mixture provides no lubrication to the bearing. However, I have only seen this undertaken with sealed bearings, were lubrication is not required.

In choosing a suitable grease, care must be taken to choose an appropriate grade. For overhauling Norman superchargers I would recommend a grease such as Shell Gadus S3 T100. This grease:

a) is suitable for roller and ball bearings (pretty damn important given that is what it is going onto… some greases used for king pin and chassis greasing will not be suitable),

b) is good for 160ºC (a high temperature range is important particularly if no water injection is used),

c) can handle higher bearing speeds,

d) is water tolerant (important if we are using water injection upstream of the supercharger), and

e) has a long service life (important as Norman superchargers are generally not fitted with grease nipples).

Seals are used in the Norman supercharger for two purposes. Firstly (and more obviously), the seals are to close the gap between the rotating shaft and the static casing to keep the boost pressure within the supercharger. In this case a poor seal means loss of boost pressure, and also a leak of (explosive!) air/fuel mixture into the engine bay. The second reason for the use of seals is more subtle. Under low load conditions (low speed), the supercharger and inlet manifold can come under vacuum, just like a normal (naturally aspirated) engine. In these conditions, a poor seal can lead to air ingress and unstable fuel/air mixtures.

The drive-end seal of the Norman superchargers are twin lip seals with a garter spring. Dimensions of the seals are shown in the table below:

Many of the original Norman seals were of leather and/or felt construction… somewhat hard to find now. A suitable replacement is Nitrile Butadiene Rubber (NBR), which has a maximum temperature of 125°C continuous. Whilst Viton (225°C) would be a better chose, it is a lot less commonly available. In addition to NBR’s temperature limits, NBR (like all materials) has a speed limit. Most seal manufacturers rate the speed limit using surface feet per minute (or meters per second). This is a measurement of how many surface feet meters) pass a given point at the seal lip per minute (second) in time. Since this method considers the shaft diameter in addition to speed, it is a better service indicator than RPM alone. A typical seal design in NBR material can operate up to 3,000 fpm (15 m/s) assuming all other operating parameters are reasonable. For Norman supercharger shaft diameters (1-1.4” diameter) this implies a speed limit of around 8500rpm (Timkin suggests this could be a little lower at 6500rpm for their TC seals). This speed limit should not be an issue given that most Norman superchargers will run at speeds similar to that of the crankshaft (~4500rpm maximum).

Most seals that I pulled out of the Norman superchargers are simple TC profile type seals. TC seals are typically rated for 5psi operation. Whilst 5psi is in the typical Norman supercharger range, 10psi is not out of the question. There are better seal profiles available (for example Parker’s LFN, LFE-S and MP seal profiles, as they are suitable up to 60psi). Note however that again availability may be an issue for these seal profiles – I have not yet been able to find a decent seal profile in the sizes required for Norman superchargersother than the simple TC seals. For interest, LFN, LFE-S, MP and TC seal profiles are shown (from left to right) in the image above.

Cheers,

Harv (deputy apprentice Norman supercharger fiddler)

327 Chev EK wagon, original EK ute for Number 1 Daughter, an FB sedan meth monster project and a BB/MD grey motored FED.

Re: Harv's Norman supercharger thread

As promised, I want to return back to discussing SU carbs. In this post I am going to deal with a significant issue - try to obtain mixture control with monster carbs.

It is possible, and fairly common, to run a single SU carburettor to feed a Norman supercharger (the 3” Norman SU is pretty rare, but a single 2” is run-of-the-mill). However, large single SU carburettors on supercharged engines can lead to a mixture spread issue. At full throttle, the supercharger is producing boost, squeezing in lots of air and lots of fuel. This requires a fairly rich needle profile. At part throttle however boost is very low (in some cases vacuum exists in the inlet manifold), and the engine behaves more like a naturally aspirated car. This then requires a normally lean needle profile. Whilst the full-throttle mixture can be tuned by finding an appropriate needle, the part throttle mixture may end up being overly rich (almost the same as full-throttle) leading to poor fuel efficiency. Whilst this issue is not too serious in race vehicles that always run full-throttle, it can be annoying in a road vehicle (poor economy and plug fouling). Finding a better needle profile may help solve the issue, though few needles are available for supercharged applications.

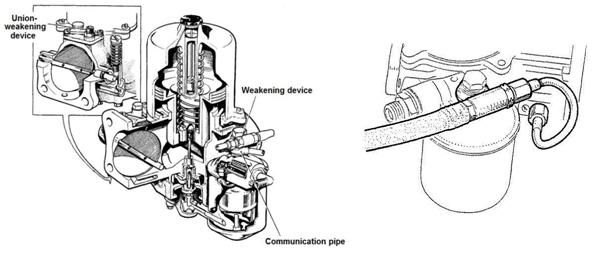

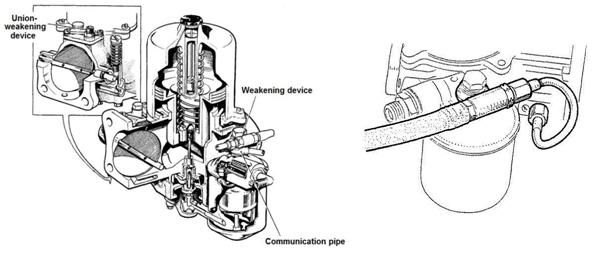

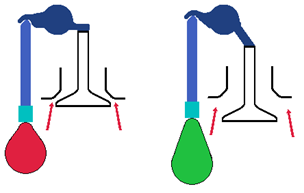

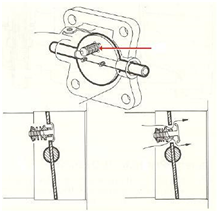

One method to get around the mixture spread issue is to use the Additional Weakening Device, which was a fitting originally used in some SU installations (eg the HIF38S, also known as the metric HIF4). I will draw below on some information from both Tuning British Leyland’s A-Series Engine by David Vizard and Tuning SU Carburettors by Speedsport Motorbooks. The images below show the weakening device as installed to original SU float bowls:

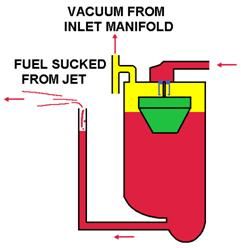

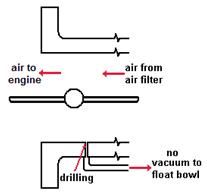

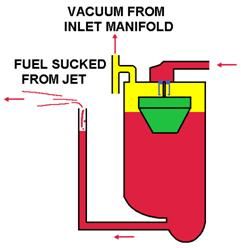

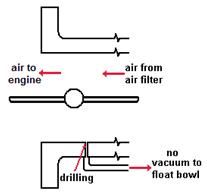

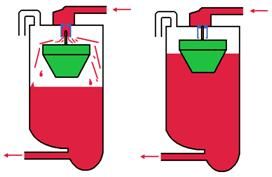

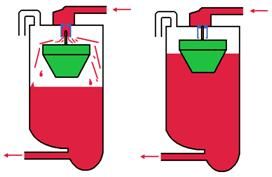

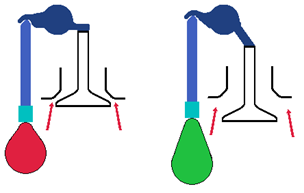

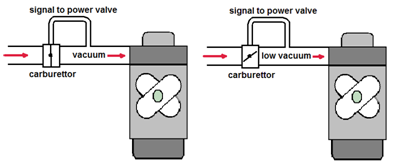

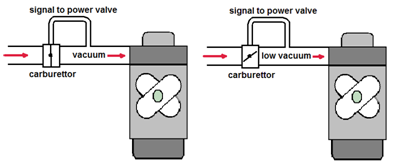

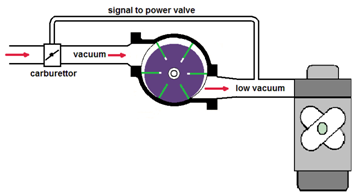

The amount of fuel delivered by an SU main jet is governed, not only by the profile of the needle presented to the airstream, but also by the height of the fuel in the jet. In simple terms, if the fuel height is lower in the jet, it is harder for the carb to “suck” out the fuel, leading to a leaner mixture. The Additional Weakening Device works (leans the mixture) by lowering the fuel level in the jet. It does this by changing the pressure differential between the end of the jet (the carb throat) and the fuel in the float bowl. Normally the fuel in the float bowl is subjected to standard air pressure, as the float bowl is vented as per the image below:

.

.

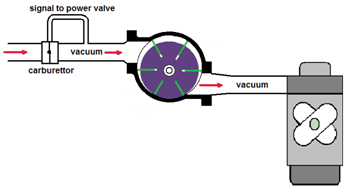

The height of fuel in the jet is then determined by the corresponding height of fuel in the float bowl (hydrostatic head, just like a water level gauge used by carpenters). The Additional Weakening Device however applies a partial vacuum to the top of the float bowl, as per the image below:

.

.

The float still controls the float bowl level at the same height, giving the same hydrostatic head to the jet. However, the vacuum above the float chamber fuel level means that the total pressure seen by the jet is lower, and hence the fuel level in the jet drops down. By controlling how much vacuum is applied to the float bowl, different fuel levels in the jet can be made, and hence different mixtures.

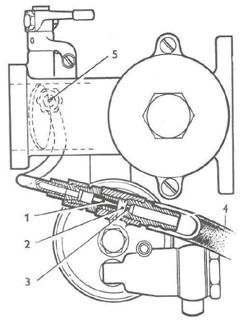

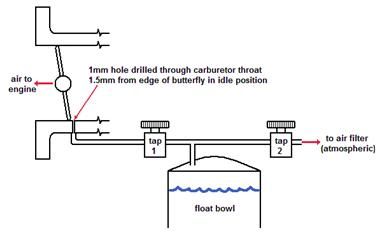

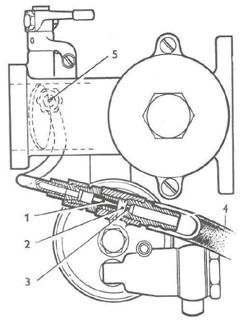

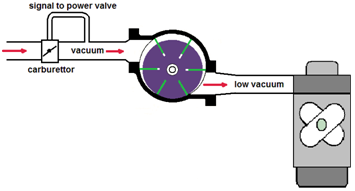

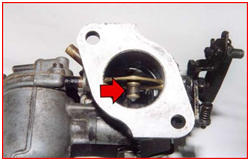

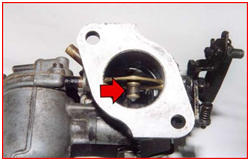

The Additional Weakening Device consists of a drilling in the carburettor throat (labelled 5 in the image below) which is connected by a flexible pipe to the top of the float bowl.

The drilling in the carburettor throat is made on the upstream side of the throttle butterfly (i.e. it supplies ported vacuum, not manifold vacuum). At the top of the float bowl a venturi (labelled as 1) is used to draw vacuum from the float bowl via a drilling (labelled as 2). The float bowl is sealed, with a vent line provided to let air into the bowl (labelled as 4). As this air is being sucked (through the float bowl) to the carburettor throat, the vent line is normally connected to the air filter to provide clean air. The amount of air that can flow through the vent line is controlled by an air bleed restriction (labelled as 3). The size of the venturi (1) is standard. The air bleed restriction diameter (3) is varied on different vehicles to determine the amount of vacuum applied (and hence the mixture strength). Note that the diameter and length of the flexible vent line (4) connecting the air bleed restriction to the air filter has a substantial effect on mixture strength.

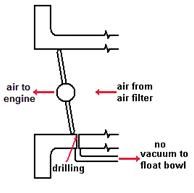

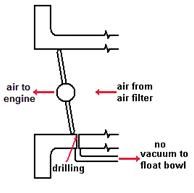

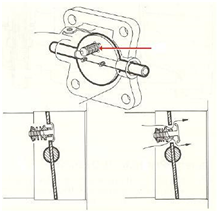

With the throttle in the normal idling position (as shown in the image to the right), the drilling in the carburettor body is located upstream of the throttle butterfly, and is not able to see manifold vacuum:

There is a very slight vacuum, but the effect on the float chamber will be negligible. This means that the Additional Weakening Device has no effect on the fuel mixture at idle.

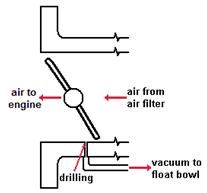

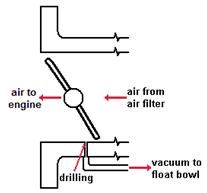

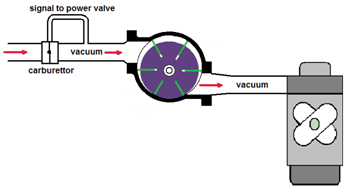

When the throttle is partly open (as per the image below), the drilling in the carburettor body becomes exposed to manifold vacuum:

This causes air to be drawn from the float bowl via the venturi. The use of a venturi (instead of a plain orifice) ensures that the air velocity will reach a maximum value which remains constant. The air bleed on top of the float bowl allows air into the float bowl, though the flow is restricted by the air bleed restriction. This gives vacuum in the float bowl, causing the fuel level in the jet to drop and the mixture to run leaner. This arrangement allows the maximum fuel mixturing weakening effect to be produced when the throttle buterfly is closed a small amount from the full open position (when only a slight vacuum is present) and ensures that further closing of the throttle does not increase the weakening effect to the point at which misfiring may occur.

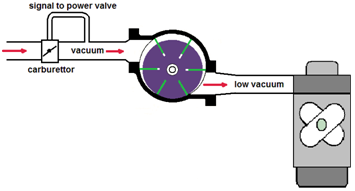

When the throttle is fully open (as per the image below), manifold vacuum decreases to a very small amount:

This small vacuum is able to act on the throttle body drilling, but is not sufficient to cause significant vacuum in the fuel bowl. In this way the Additional Weakening Device is not able to affect the mixture under full throttle operation.

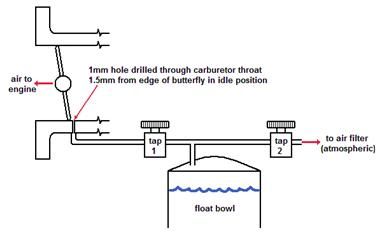

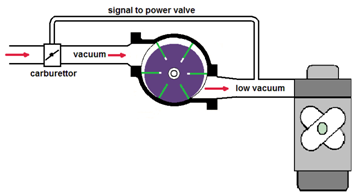

Whilst a fairly simple piece of kit, the Additional Weakening Device consists of the fine air bleed restriction and the venturi. Both of these items have been tuned to a particular needle, jet and vacuum combination, and are not adjustable. If a factory Additional Weakening Device is used on a Norman supercharged vehicle, it may not behave as intended – there is a risk of lean-out and resulting knocking (pinging). It is however possible to build a fully adjustable Additional Weakening Device from scratch. The scratch-built device has the same configuration as the factory Additional Weakening Device, as shown in the image below:

However, both the venturi and the air bleed restriction are replaced with simple needle valves (taps). This allows the amount of vacuum applied to the float bowl to be readily tuned by either restricting the air flowing in, or the vacuum pulling air out of the bowl.

In building the system, it is important to have a running supercharger with the idle pretty much set. This allows the throttle plate position at idle to be determined. A hole is then drilled 1½mm (~0.06”) from the edge of the butterfly in the relevant (upstream) side of the carburettor body. Remember, when the butterfly opens the hole must be in such a position that the butterfly will sweep over it, effectively moving it from upstream of the butterfly to downstream so that it communicates vacuum to the system. If the idle had not been set first, there is a chance that the hole ends up on the wrong side of the throttle plate. Suitable adaptors are then used to connect the carburettor body hole via vacuum hose to Tap 1. The taps need to be fuel resistant and able to pass a reasonable amount of air (you should be able to blow through it relatively easily when it’s fully open) – brass air compressor fittings are not a bad choice. Tap 1 is then connected to the top of the fuel bowl, again using vacuum hose. The fuel bowl needs to be sealed, with the vent of the fuel bowl connected to Tap 2. The other side of Tap 2 is then fitted into the air cleaner. During tuning of the device, it’s handy to mount Tap 2 inside the car via a fairly long length of vacuum hose, with the other end looping back into the air filter. This hose can then be shortening back once the tuning is complete.

Care needs to be taken in tuning the system. Adjusting Tap 1 will change the rate at which the air is drawn out of the float bowl, whilst adjusting Tap 2 changes the rate that air can flow in to the float bowl. The balance of the two adjustments determines the vacuum inside the float bowl, and hence the mixture setting at part-throttle. lf too big a vent is used, the air will flow back into the float bowl as fast as it is being evacuated, cancelling out the effect we are trying to achieve. On the other hand if it's too small, then the vacuum created in the float bowl will be sufficient to totally stop the fuel going into the engine, causing the engine to stall when the throttle is opened.

To tune the Additional Weakening Device:

a) Establish just how much Tap 2 needs to be open. We want Tap 2 to be controlling the air flow to the float bowl, but not strangling it to the point that the a vacuum develops in the float bowl (and the mixture changes) under full load. To do this, close Tap 1 so that no vacuum is communicated to the float bowl. Set Tap 2 fully open so that the float bowl is adequately vented. Drive the vehicle and check the third gear 30-60mph flat-out acceleration time. To do this, it's best to start below 30mph and have an offside start the stopwatch as the speedo passes 30mph. Hit it again when it reaches 60mph, but always drive on past that speed by a few mph.

b) When you are sure the 30-60mph acceleration times are consistent, close Tap 2 slightly and do the test again. We are looking for the point where Tap 2 begins to control the air flow to the float bowl by strangling it to the point that the a vacuum develops in the float bowl (and the mixture changes). Continue repeating the test (closing Tap 2 a little more each time) until you find the point at which the 30-60mph acceleration times starts to deteriorate. ln some instances you may find that Tap 2 can go all the way closed without affecting the performance, in which case open Tap 2 about two full turns. Once you find the point that the performance starts to deteriorate, open Tap 2 slightly to restore the engine's performance.

c) Open Tap 1 very slightly and check that the engine picks up properly. Take the car out on the road and drive at your most used cruising speeds. These may range from your in-town cruising speed of around 35mph (55km/h) up to freeway cruising speeds of 70mph (110km/h). If you have a vacuum gauge, note the vacuum at each speed you test at (the road should be dead flat if using a vacuum gauge). What you are looking for is the engine beginning to run lean and surge. This is the same thing that the standard FB/EK Holden motor will do if the main metering jet is too small. When lean surge starts, the car becomes slightly hesitant, and can begin to lightly miss.

d) lf the car is not surging, open Tap 1 a little bit more, making the fuel further small increment. Take the car out and try it again. Continue repeating the test (opening Tap 1 a little more each time) until you feel the car run into lean surge under cruise. When this happens, close Tap 1 slightly so that the lean surge just disappears.

e) Now re-check your 30-60mph acceleration time. The acceleration time should not have changed from those achieved originally. lf it has changed, it's because there is a slight reduction in mixture strength at full throttle. The Additional Weakening Device does not change the mixture under full throttle conditions. However, if the engine is under-carburretted, the engine may pull fuel from the float chamber fast enough to overtake the air supply back into the float chamber via Tap 2. lf this is the case, you will have to compensate for this effect by one of two means, either increase the richness of the mixture by having a slightly slimmer needle at the top end, or sacrifice some of the potential weakening effect by opening Tap 2 slightly wider.

f) Remember that in playing around with mixture strengths there is a chance that the engine runs lean. It is a good idea to keep an eye on the spark plug readings for any signs of running overly lean until you are confident the mixture is right.

Note that the above process has been set-up for simple testing. It is equally possible to tune the Additional Weakening Device on a dyno by setting Tap 2 to peak power then adjusting Tap 1 for a good mixture quality (by exhaust gas analysis) under cruise conditions.

Cheers,

Harv (deputy apprentice Norman supercharger fiddler).

It is possible, and fairly common, to run a single SU carburettor to feed a Norman supercharger (the 3” Norman SU is pretty rare, but a single 2” is run-of-the-mill). However, large single SU carburettors on supercharged engines can lead to a mixture spread issue. At full throttle, the supercharger is producing boost, squeezing in lots of air and lots of fuel. This requires a fairly rich needle profile. At part throttle however boost is very low (in some cases vacuum exists in the inlet manifold), and the engine behaves more like a naturally aspirated car. This then requires a normally lean needle profile. Whilst the full-throttle mixture can be tuned by finding an appropriate needle, the part throttle mixture may end up being overly rich (almost the same as full-throttle) leading to poor fuel efficiency. Whilst this issue is not too serious in race vehicles that always run full-throttle, it can be annoying in a road vehicle (poor economy and plug fouling). Finding a better needle profile may help solve the issue, though few needles are available for supercharged applications.

One method to get around the mixture spread issue is to use the Additional Weakening Device, which was a fitting originally used in some SU installations (eg the HIF38S, also known as the metric HIF4). I will draw below on some information from both Tuning British Leyland’s A-Series Engine by David Vizard and Tuning SU Carburettors by Speedsport Motorbooks. The images below show the weakening device as installed to original SU float bowls:

The amount of fuel delivered by an SU main jet is governed, not only by the profile of the needle presented to the airstream, but also by the height of the fuel in the jet. In simple terms, if the fuel height is lower in the jet, it is harder for the carb to “suck” out the fuel, leading to a leaner mixture. The Additional Weakening Device works (leans the mixture) by lowering the fuel level in the jet. It does this by changing the pressure differential between the end of the jet (the carb throat) and the fuel in the float bowl. Normally the fuel in the float bowl is subjected to standard air pressure, as the float bowl is vented as per the image below:

.

.The height of fuel in the jet is then determined by the corresponding height of fuel in the float bowl (hydrostatic head, just like a water level gauge used by carpenters). The Additional Weakening Device however applies a partial vacuum to the top of the float bowl, as per the image below:

.

.The float still controls the float bowl level at the same height, giving the same hydrostatic head to the jet. However, the vacuum above the float chamber fuel level means that the total pressure seen by the jet is lower, and hence the fuel level in the jet drops down. By controlling how much vacuum is applied to the float bowl, different fuel levels in the jet can be made, and hence different mixtures.

The Additional Weakening Device consists of a drilling in the carburettor throat (labelled 5 in the image below) which is connected by a flexible pipe to the top of the float bowl.

The drilling in the carburettor throat is made on the upstream side of the throttle butterfly (i.e. it supplies ported vacuum, not manifold vacuum). At the top of the float bowl a venturi (labelled as 1) is used to draw vacuum from the float bowl via a drilling (labelled as 2). The float bowl is sealed, with a vent line provided to let air into the bowl (labelled as 4). As this air is being sucked (through the float bowl) to the carburettor throat, the vent line is normally connected to the air filter to provide clean air. The amount of air that can flow through the vent line is controlled by an air bleed restriction (labelled as 3). The size of the venturi (1) is standard. The air bleed restriction diameter (3) is varied on different vehicles to determine the amount of vacuum applied (and hence the mixture strength). Note that the diameter and length of the flexible vent line (4) connecting the air bleed restriction to the air filter has a substantial effect on mixture strength.

With the throttle in the normal idling position (as shown in the image to the right), the drilling in the carburettor body is located upstream of the throttle butterfly, and is not able to see manifold vacuum:

There is a very slight vacuum, but the effect on the float chamber will be negligible. This means that the Additional Weakening Device has no effect on the fuel mixture at idle.

When the throttle is partly open (as per the image below), the drilling in the carburettor body becomes exposed to manifold vacuum:

This causes air to be drawn from the float bowl via the venturi. The use of a venturi (instead of a plain orifice) ensures that the air velocity will reach a maximum value which remains constant. The air bleed on top of the float bowl allows air into the float bowl, though the flow is restricted by the air bleed restriction. This gives vacuum in the float bowl, causing the fuel level in the jet to drop and the mixture to run leaner. This arrangement allows the maximum fuel mixturing weakening effect to be produced when the throttle buterfly is closed a small amount from the full open position (when only a slight vacuum is present) and ensures that further closing of the throttle does not increase the weakening effect to the point at which misfiring may occur.

When the throttle is fully open (as per the image below), manifold vacuum decreases to a very small amount:

This small vacuum is able to act on the throttle body drilling, but is not sufficient to cause significant vacuum in the fuel bowl. In this way the Additional Weakening Device is not able to affect the mixture under full throttle operation.

Whilst a fairly simple piece of kit, the Additional Weakening Device consists of the fine air bleed restriction and the venturi. Both of these items have been tuned to a particular needle, jet and vacuum combination, and are not adjustable. If a factory Additional Weakening Device is used on a Norman supercharged vehicle, it may not behave as intended – there is a risk of lean-out and resulting knocking (pinging). It is however possible to build a fully adjustable Additional Weakening Device from scratch. The scratch-built device has the same configuration as the factory Additional Weakening Device, as shown in the image below:

However, both the venturi and the air bleed restriction are replaced with simple needle valves (taps). This allows the amount of vacuum applied to the float bowl to be readily tuned by either restricting the air flowing in, or the vacuum pulling air out of the bowl.

In building the system, it is important to have a running supercharger with the idle pretty much set. This allows the throttle plate position at idle to be determined. A hole is then drilled 1½mm (~0.06”) from the edge of the butterfly in the relevant (upstream) side of the carburettor body. Remember, when the butterfly opens the hole must be in such a position that the butterfly will sweep over it, effectively moving it from upstream of the butterfly to downstream so that it communicates vacuum to the system. If the idle had not been set first, there is a chance that the hole ends up on the wrong side of the throttle plate. Suitable adaptors are then used to connect the carburettor body hole via vacuum hose to Tap 1. The taps need to be fuel resistant and able to pass a reasonable amount of air (you should be able to blow through it relatively easily when it’s fully open) – brass air compressor fittings are not a bad choice. Tap 1 is then connected to the top of the fuel bowl, again using vacuum hose. The fuel bowl needs to be sealed, with the vent of the fuel bowl connected to Tap 2. The other side of Tap 2 is then fitted into the air cleaner. During tuning of the device, it’s handy to mount Tap 2 inside the car via a fairly long length of vacuum hose, with the other end looping back into the air filter. This hose can then be shortening back once the tuning is complete.

Care needs to be taken in tuning the system. Adjusting Tap 1 will change the rate at which the air is drawn out of the float bowl, whilst adjusting Tap 2 changes the rate that air can flow in to the float bowl. The balance of the two adjustments determines the vacuum inside the float bowl, and hence the mixture setting at part-throttle. lf too big a vent is used, the air will flow back into the float bowl as fast as it is being evacuated, cancelling out the effect we are trying to achieve. On the other hand if it's too small, then the vacuum created in the float bowl will be sufficient to totally stop the fuel going into the engine, causing the engine to stall when the throttle is opened.

To tune the Additional Weakening Device:

a) Establish just how much Tap 2 needs to be open. We want Tap 2 to be controlling the air flow to the float bowl, but not strangling it to the point that the a vacuum develops in the float bowl (and the mixture changes) under full load. To do this, close Tap 1 so that no vacuum is communicated to the float bowl. Set Tap 2 fully open so that the float bowl is adequately vented. Drive the vehicle and check the third gear 30-60mph flat-out acceleration time. To do this, it's best to start below 30mph and have an offside start the stopwatch as the speedo passes 30mph. Hit it again when it reaches 60mph, but always drive on past that speed by a few mph.

b) When you are sure the 30-60mph acceleration times are consistent, close Tap 2 slightly and do the test again. We are looking for the point where Tap 2 begins to control the air flow to the float bowl by strangling it to the point that the a vacuum develops in the float bowl (and the mixture changes). Continue repeating the test (closing Tap 2 a little more each time) until you find the point at which the 30-60mph acceleration times starts to deteriorate. ln some instances you may find that Tap 2 can go all the way closed without affecting the performance, in which case open Tap 2 about two full turns. Once you find the point that the performance starts to deteriorate, open Tap 2 slightly to restore the engine's performance.

c) Open Tap 1 very slightly and check that the engine picks up properly. Take the car out on the road and drive at your most used cruising speeds. These may range from your in-town cruising speed of around 35mph (55km/h) up to freeway cruising speeds of 70mph (110km/h). If you have a vacuum gauge, note the vacuum at each speed you test at (the road should be dead flat if using a vacuum gauge). What you are looking for is the engine beginning to run lean and surge. This is the same thing that the standard FB/EK Holden motor will do if the main metering jet is too small. When lean surge starts, the car becomes slightly hesitant, and can begin to lightly miss.

d) lf the car is not surging, open Tap 1 a little bit more, making the fuel further small increment. Take the car out and try it again. Continue repeating the test (opening Tap 1 a little more each time) until you feel the car run into lean surge under cruise. When this happens, close Tap 1 slightly so that the lean surge just disappears.

e) Now re-check your 30-60mph acceleration time. The acceleration time should not have changed from those achieved originally. lf it has changed, it's because there is a slight reduction in mixture strength at full throttle. The Additional Weakening Device does not change the mixture under full throttle conditions. However, if the engine is under-carburretted, the engine may pull fuel from the float chamber fast enough to overtake the air supply back into the float chamber via Tap 2. lf this is the case, you will have to compensate for this effect by one of two means, either increase the richness of the mixture by having a slightly slimmer needle at the top end, or sacrifice some of the potential weakening effect by opening Tap 2 slightly wider.

f) Remember that in playing around with mixture strengths there is a chance that the engine runs lean. It is a good idea to keep an eye on the spark plug readings for any signs of running overly lean until you are confident the mixture is right.

Note that the above process has been set-up for simple testing. It is equally possible to tune the Additional Weakening Device on a dyno by setting Tap 2 to peak power then adjusting Tap 1 for a good mixture quality (by exhaust gas analysis) under cruise conditions.

Cheers,

Harv (deputy apprentice Norman supercharger fiddler).

327 Chev EK wagon, original EK ute for Number 1 Daughter, an FB sedan meth monster project and a BB/MD grey motored FED.

Re: Harv's Norman supercharger thread

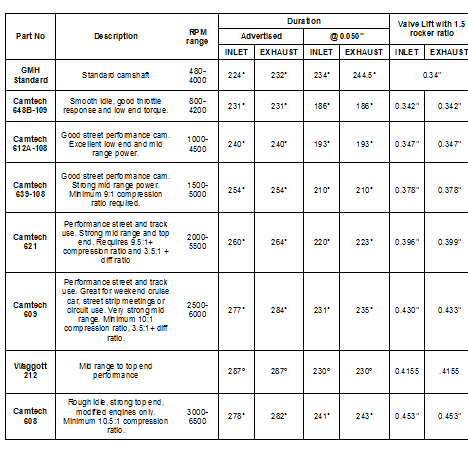

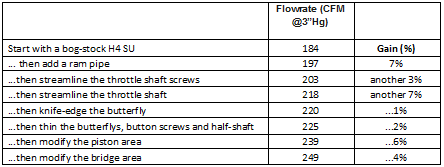

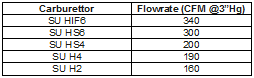

For this post I will continue on with some info on SU carbs, focussing on the float bowl capacity.

There is no doubt that adding 50-100% more horsepower will increase the fuel demand on a vehicle. The typical full-throttle engine fuel requirement is 0.5lb per horsepower per hour, which equates to 0.0833 gallons of petrol per hour per horsepower. Our Norman supercharged grey motor is likely to achieve a 50-100% increase in power, giving 110-150 horsepower. The fuel requirement is thus likely to be of the order of 8-12gph on pump fuel. Eldred flags within Supercharge! that feeding the vehicle can become a constraint, both via the fuel pump (which I will deal with separately) and via the carburetor float bowl. Most road-going Norman supercharged applications running on petrol will be unlikely to hit this limit, as the standard SU needle and seat will flow of the order of 15gph. A single (2”) SU needle and seat is thus likely to cope, and if we are running twin (1¾”) SUs we should have absolutely no issue. Note though that for red motors our horsepower may increase to double that shown above. This would mean that even twin SUs become marginal for red motor petrol flow. Regardless of what motor we are running, the issue above becomes increasingly important if running methanol (bear in mind that you need to flow 2-2½ times as much methanol as petrol)… a methanol slurping grey will be marginal with two standard SU float bowls, whilst a red motor meth monster will still be hungry being fed by four.

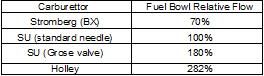

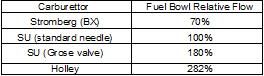

The carburetor float bowl is generally constrained by the size (diameter) of the fuel inlet needle and seat. A typical SU aftermarket (viton-tipped) needle and seat has a diameter of 0.090”. One improvement made since Eldred’s time is the availability of Grose jets (another type of needle and seat) for SUs. A Grose Jet is not a needle, but instead consists of two ball bearings in a solid brass cage, one large one that is moved by the float, and a smaller one that is moved by the bigger ball bearing until it shuts off the flow of fuel. The original reasoning behind the Grose Jets' design was to lower the liklihood that they would jam or stick (the original brass-tipped needless were reknowned for jamming - a lot less of a problem with modern viton tips). Grose-Jet inlet valves are available with orifices of 0.084", 0.099” and 0.125” diameters. As a comparison, Holley needle-and-seat assemblies are typically 0.097-0.150” diameter, whilst single-barrel Stromberg needle and seats ranged from 0.07-0.093” for Holdens (the aftermarket ones now available are typically 0.076” diameter). Note however that along with the diameter of the needle and seat, the fuel inlet pressure has a part to play. SU carburettors are happy to run on 1½-3½ psi, and overflow around 5 psi. Holley carburettors run happily at 5-7psi, whilst Stromberg carburettors operate on approximately 2½-4½ psi of fuel inlet pressure. Fuel flow is proportional to the square of the orifice diameter (i.e. flow α diameter2), and to the square root of inlet pressure (i.e. flow α√pressure). Calculating this through shows that a typical SU fuel bowl and standard needle and seat will have flow doubled if changing out to a Grose valve. The Grose-valved SU will flow nearly three times as much as a single-barrel Stromberg, but only two-thirds as much as a Holley i.e:

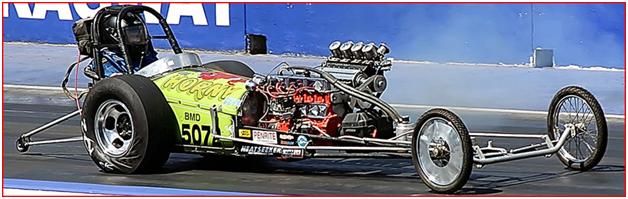

The upshot of this is that if the standard SU float bowl is constraining the vehicle, changing to a Grose valve may solve the problem. If fuel flow is still constrained, the use of Holley float bowls (on SU carbs) may help. This sounds a little off-centre, but is exactly the solution implemented on the Norman supercharged 1963 Lil Horny Devil slingshot rail currently owned by Chris Batey:

http://www.youtube.com/watch?v=4mLzZfjMamY

http://www.youtube.com/watch?v=pWrMQfr8Zr8

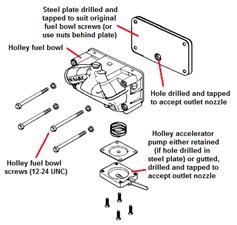

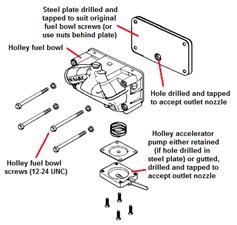

The Holley float bowl and associated parts are readily available and relatively cheap. The float bowl can be bolted to a piece of flat steel plate to form the rear of the bowl, as can be seen in the image below:

The original Holley mounting screws and gasket can be utilized. Note that Chris’ setup has two float bowls installed, one at either end of the inlet manifold (see photo below … the second bowl can be seen just sticking out from under the right-hand SU inlet trumpet):

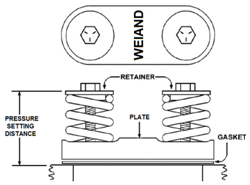

Care needs to be taken in locating the Holley float bowl at an appropriate height relative to the SU carburetor jet, as the fuel bowl level affects the height of the fuel in the jet, and hence the mixture strength. The diagram below shows how the bowl may be constructed:

Note that for the outlet it is possible to drill and tap a hole into the back of the steel plate to accept a nozzle. In this case the accelerator pump assembly is retained to seal the bottom of the fuel bowl. Alternatively, fuel can be taken from the bottom of the accelerator pump assembly by removing the diaphragm, spring and pump arm and then tapping bottom of the float bowl to accept a nozzle. Note that the accelerator pump check ball and retainer strap, as shown in the photograph below should also be removed and the hole drilled out to remove the potential restriction:

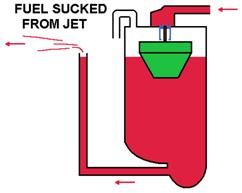

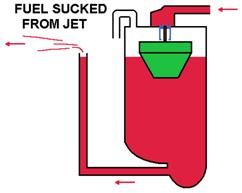

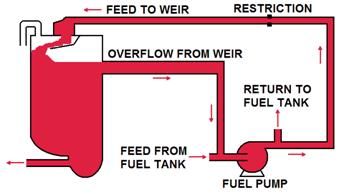

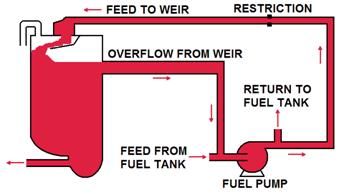

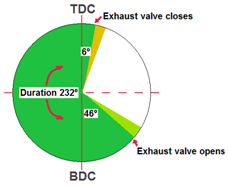

For all-out race vehicles which wish to retain the SU carburettors, Eldred describes a modification to the SU float bowl which makes is operate as a weir fueled by a large capacity fuel pump. The “weir” is simply a hole drilled in the side of the float bowl at the desired fuel level. The standard SU float bowl operates as shown in the image below:

The float (shown in green) sits on top of the fuel level. As the fuel level drops (as per the left-hand image) the float drops with it, lowering and opening the needle valve. As the fuel valve rises to the desired level (as shown in the right hand image) the float rises, pushing u the needle and closing off fuel flow to the bowl. In Eldred’s weir modification, the float is fully removed, as per the image below:

The fuel pump is able to freely supply fuel to the bowl at all times. Any fuel that the engine does not consume gets recycled back to the fuel tank. A restriction is placed into the feed line to the float bowl to stop the fuel flow from being excessive (and hence overflowing the float bowl). Provided the fuel pump has a high enough capacity, the fuel bowl level will never drop any lower than the weir overflow level. Whilst this system has more plumbing than the standard needle and seat, it is very resistant to the issue of jamming or plugging of the needle orifice.

Cheers,

Harv (deputy apprentice Norman supercharger fiddler).