Gents,

I may have this wrong (correct me if I have), but I think the basic process should be:

a) select the diff, and have it narrowed to fit the FB/EK shell and desired wheels.

b) make up a set of diff mounting saddles, but don't weld them on just yet.

c) mount the diff, engine and gearbox into the car (this will require some packing and clamping as the diff is loose.

d) get the car at ride height, and on level ground.

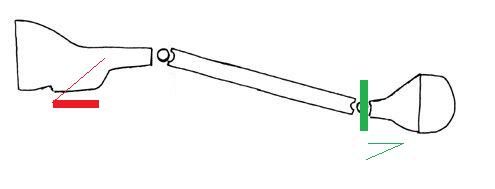

e) put a spirit level/protractor/angle finder onto the transmission oil pan rails (kinda where the red block is on the drawing below). The gearbox mounts should be shimmed so that the gearbox is sitting tail up (like the engine fan is trying to dig into the ground) by between 1-3 degrees.

f) put a spirit level/protractor/angle finder onto the diff pinion flange (kinda where the green block is on the drawing below). Rotate the diff so that the diff is sitting nose-down (like the pinion flange is trying to dig into the ground) by the same amount as the gearbox was sitting tail-down (1-3 degrees). Tack the diff saddles in place.

g) remove the diff and final weld the saddles on.

This makes the driveline the same angle at each end, and under load (as the diff snout torques up) the angles come close to zero. There is a fair bit of faffing around trying to correct for uneven ground and measuring angles at 90 degrees to how you want to measure them.

Cheers,

Harv.

327 Chev EK wagon, original EK ute for Number 1 Daughter, an FB sedan meth monster project and a BB/MD grey motored FED.