Page 29 of 76

Posted: Sat Mar 07, 2009 5:36 pm

by mrs ratbox

Posted: Sat Mar 07, 2009 5:51 pm

by EK283

Yep,

You have no space bugger!!!

The coil overs are right in the way so the panhard is the only answer in this case.

It should still work ok. When I had a panhard rod on the race car it oversteered one way and understeered the other. Seriously though I think your whole package will be ok ( your not going to circuit race I hope ).

If your going to drag the car research the way the rod is fitted.From memory I think you need to have the rod attached to the right side of the body and to the left side of the diff . When you accelerate the body torque will push the right rear down, so you want the rod to push the left of the diff down cause this side has the least traction ( If that makes sense ).

Regards Greg

Posted: Sat Mar 07, 2009 5:58 pm

by macca4551

Hi Garry,

Up till now I can't fault anything you have done. Great job.

But that Panhard Bar will give you problems. You indicated that the diff will move 4.5mm from full extension to full compression. That in itself is too much, but have you checked sideways movement on uneven travel, meaning one side up and one side down. I think you will find it will move way more. The Panhard Bar should always run parallel to the diff housing and be as long as practical. I realise that you have space restrictions, but also believe you will kick yourself for not making the room for a Watts Link.

I hope you look at this as constructive criticism, I am certainly not trying to pick your awesome work. I just believe that you have the know how to do this particular part of your build better.

I Hope I'm not out of line.

Kind regards,

Steve

Posted: Sat Mar 07, 2009 6:43 pm

by Smooth customs

Well I will put in my two cents worth now

Lets see if this one can be miss construed.

You deleted a watts linkage because of fuel capacity, stability under power and cornering is not as important and how much fuel you have?

A different design of the tank, with a higher top. but that will decrease your lugage space in the boot!

Are you are going to brace your 4 bar brackets on the diff and gusset the shock mounts.

As side twist on these can be excessive, under load.

Will you be having a rear seat, as the 4 bars have intruded into this area.

why not just box the complete seat base area to allow more room for exhaust.

I have been in the same situation many times during the design and build of cars, and you have to allow for everything from the start.

Sometimes you redesign and rethink the hows and wheres several times before starting to fabricate.

Posted: Sat Mar 07, 2009 7:12 pm

by Smooth customs

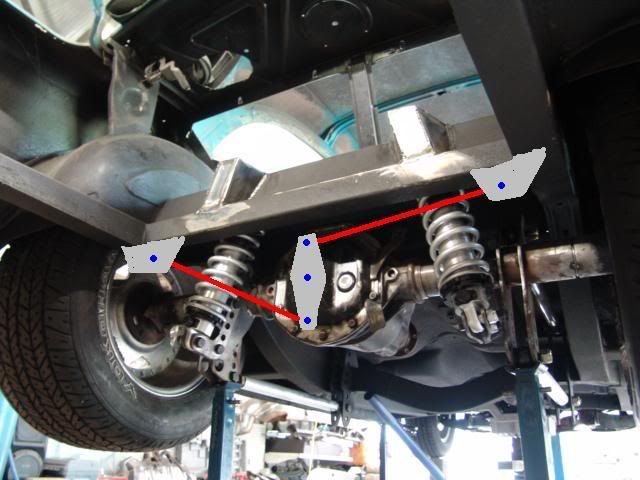

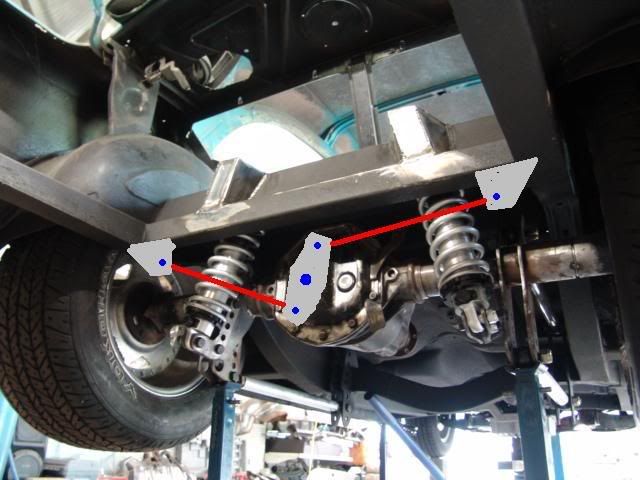

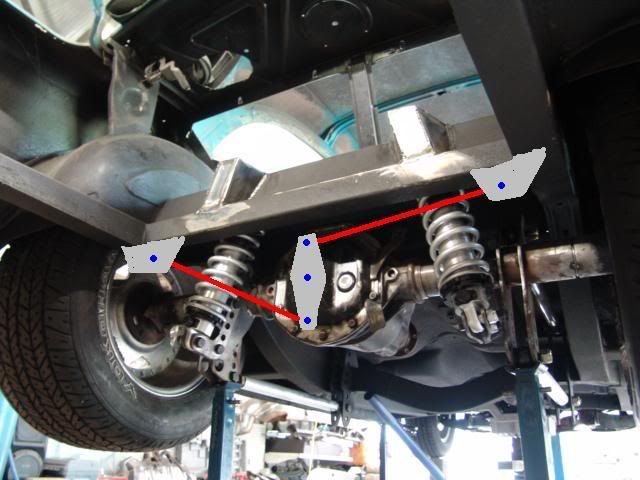

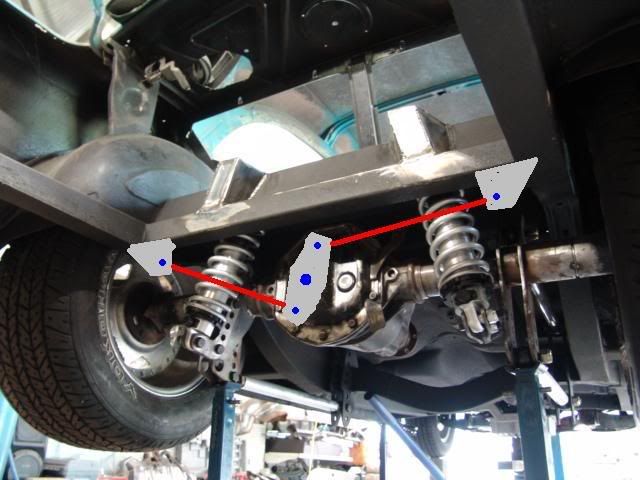

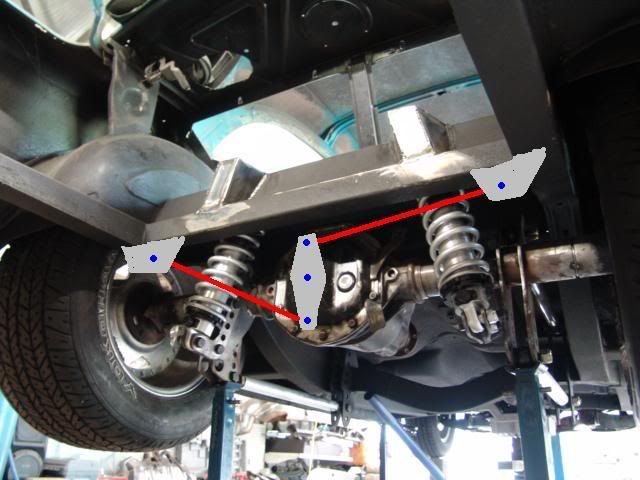

Here are some photos of how I have set up a similar rear end.

The first is in a Hot rod, with coil overs

This last one had to be designed around the minimum of space.

Allowing for over six inches of suspension movement, watts linkage and exhaust. Something that had to be designed around a lot of obstacles, and allow for a rear seat.

Sorry about the photo, but it is the only one I could find on short notice.

May change it when I can find the ones I am looking for.

Posted: Sat Mar 07, 2009 7:22 pm

by V8EK4us

Smooth customs wrote:Well I will put in my two cents worth now

Lets see if this one can be miss construed.

You deleted a watts linkage because of fuel capacity, stability under power and cornering is not as important and how much fuel you have?

A different design of the tank, with a higher top. but that will decrease your lugage space in the boot!

You are going to brace your 4 bar brackets on the diff and gusset the shock mounts.

As side twist on these can be excessive, under load.

Will you be having a rear seat, as the 4 bars have intruded into this area.

why not just box the complete seat base area to allow more room for exhaust.

I have been in the same situation many times during the design and build of cars, and you have to allow for everything from the start.

Sometimes you redesign and rethink the hows and wheres several times before starting to fabricate.

Thanks Smooth,

The watt was never on the drawing board "originally". I have sent Steve a PM to get more info, but just had a thought of mounting the watts infront of the diff

. It will work exactly the same and I should be able to get it in there ....... maybe

.

The tank top is already 50mm above the original tank top and I want to retain the original fuel filler position and replace the cap with an Earl's filler. Just my silly preference again that's causing my headaches

.

The diff brackets are all only tacked atthe moment and will be fully welded (stagered to avoid distorting the housing) and baced prior to paint.

The back seat was prefitted and adjusted prior to the 4 link tunnels being made. The seat does fit, the only section effected is under the back section of the seat. I know that cutting out all the rear floor (under the seat) and boxing it higher would have made things easier for me, but I want the car to look "factory" underneath in a strange sort of way by keeping as much of the original floorpan as possible, specially because the floor pan was free of dents. I know it probably seems silly, but it's what I wanted from day one so I have persisted in trying to finish it that way.

Smooth customs wrote:I have been in the same situation many times during the design and build of cars, and you have to allow for everything from the start.

Sometimes you redesign and rethink the hows and wheres several times before starting to fabricate.

I'm hearing you Smooth, I design and build Plate alloy Boats (my job) from scratch both manually and using AutoCad and that is fun because neary everthing on a boat is curved!!

Basically, the headaches I'm having with the Watts link versus panard and getting it in is all self inflicted by my personal preference to keep the car from looking like its had it guts ripped out and replaced with flat plate.......

Thanksagain for the feedback, much appretiated.

Posted: Sat Mar 07, 2009 7:30 pm

by Smooth customs

You are doing a great job, and I can understand what you are trying to achieve.

Its never as easy as we initially think, or others looking on will understand.

I wish it was.

A forward mounted Watts linkage can be made work, it just requires a little more work!

Posted: Sat Mar 07, 2009 8:05 pm

by V8EK4us

Hi Smooth,

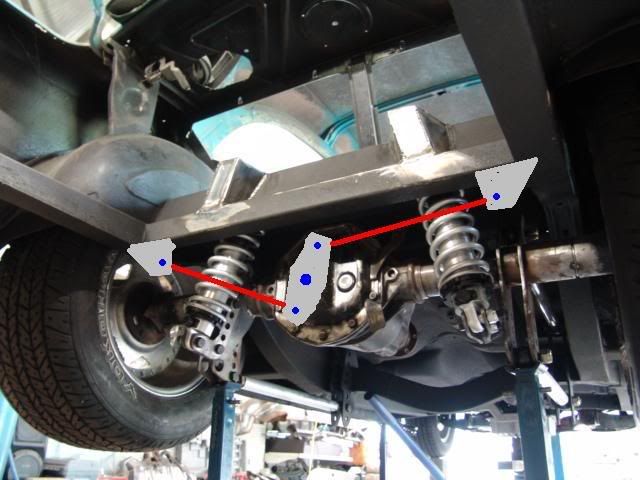

Maybe I should set it up this way, keeping both mounts at the top will allow the exhaust to be run under both brackets. There is no room to run one bracket low (as would be the prefered setup):

Posted: Sat Mar 07, 2009 8:26 pm

by ekturbo

I am truly impressed by the work your doing. I spoke to an engineer today and he said in qld this sort of setup would never pass,but, unofficially he told me to make it look factory as much as possible(specially the tubs and chassis) and will probably never be noticed. Bloody silly govt depts in qld that don`t let you upgrade the suspension with an engineers approval, but allow you to put in way more hp than the factory intended.Really glad you have done this so it will give me a reference, not that I would do it as it illegal here

Posted: Sat Mar 07, 2009 9:01 pm

by Smooth customs

V8EK4us wrote:Hi Smooth,

Maybe I should set it up this way, keeping both mounts at the top will allow the exhaust to be run under both brackets. There is no room to run one bracket low (as would be the prefered setup):

Unfortunatly that set up wont work, as both the arms must be parellel to

the ground at ride height, as in the photos I posted.And both move the same amount as the suspension does, this is how the diff remains centralised at all times

I thought about your exhaust going under the diff, but the tank and shocks will block it from being routed around them to the rear . As it would be too low run under the tank and not a desirable thing to do.

Posted: Sat Mar 07, 2009 9:11 pm

by EK283

Gary,

No good mate. The bars need to be parallel to work otherwise you will suffer from binding components. If you look at how the watts link work (on the net heaps of info ) they need to go up and down on the same plane and need to be the same length.

You could run 1 pipe over one rod and 1 under the other. If you look at smooth customs photos this is how they should be set up.

Same as the panhard the bars need to be parralel to the diff. I will get some shots of my setup just for comparison.

The link is the best way to avoid all sideway movement from up and down extreme travel.

I had 3 goes at mine before I got it right but the effort is truly worth it.

Regards Greg

Posted: Sat Mar 07, 2009 9:14 pm

by EK283

Sorry smooth customs you beat me to it ( Im slow with the keyboard ) !!!!

Regards Greg

Posted: Sat Mar 07, 2009 9:20 pm

by V8EK4us

Posted: Sat Mar 07, 2009 10:47 pm

by EK283

Gary,

Your going to hate me for this, but no the link will not work like this either.

When you look at the pic imagine the diff coming down for example under braking.

The right link wants to go up with the body and because of its arc from its locating point on the center bracket will want to "push" inward.

The left link wants to go up also and because of its arc from its locating

point will want to "pull" outward. What you get is a formular from a man much smarter than me anyway, for every action there is an equal but opposite reaction. This will try and move the center plane to the left and bind the links.

In essence what we see here is the up and down planes of the links being tilted over in your case to the right, but the diff wants to go straight up and down!

To make the links work they need to be at 90 degrees to the up and down plane and parallel to each other so the arcs on both sides are equal and not fighting each other.The center bracket must also be at 90 degrees to the links for optimum travel without binding.

I have tried what you have suggested and have broken rose joints because of it and Im lucky because I have leaf springs that held the diff in. Yes and the watts link does work with leaf springs as long as you haven't got heaps of opposite end diff travel.

I know its frustrating but you need to get this right so there is no catastrophic failures ( did I spell that right ?).

Regards Greg

Posted: Sun Mar 08, 2009 1:11 am

by V8EK4us