Page 23 of 80

Re: Chev EK

Posted: Mon Mar 28, 2016 6:34 pm

by EK283

Oz_Ek

I have a late Torana front and am using HQ style stub axles with HQ cast iron callipers and redrilled P76 discs.

It's funny but I have talked to a couple of different brake experts and they have said the HQ Holden brake set up is hard to beat as a standard set up

Both the callipers and rear wheel cylinders are one of the biggest in regards to volume and they have a very big booster as well.

Because of the room restriction near the bonnet hinge I have settled for a Gemini booster and &*#@ XB master, we shall see how it goes or stops I mean. Anyway if the combo is not up to scratch I'll just muck around until it suits both the engineer and my driving style

Regards Greg

Re: Chev EK

Posted: Tue Mar 29, 2016 11:37 am

by EK283

Progress !!!!

Body off the rotisserie its free !!!!

I have to work the beaver still where there's damage and need to do the lead wiping on all the factory joints. I have never done this before so another challenge coming my way !!!!

Regards Greg

Re: Chev EK

Posted: Sat Apr 02, 2016 9:42 pm

by EK283

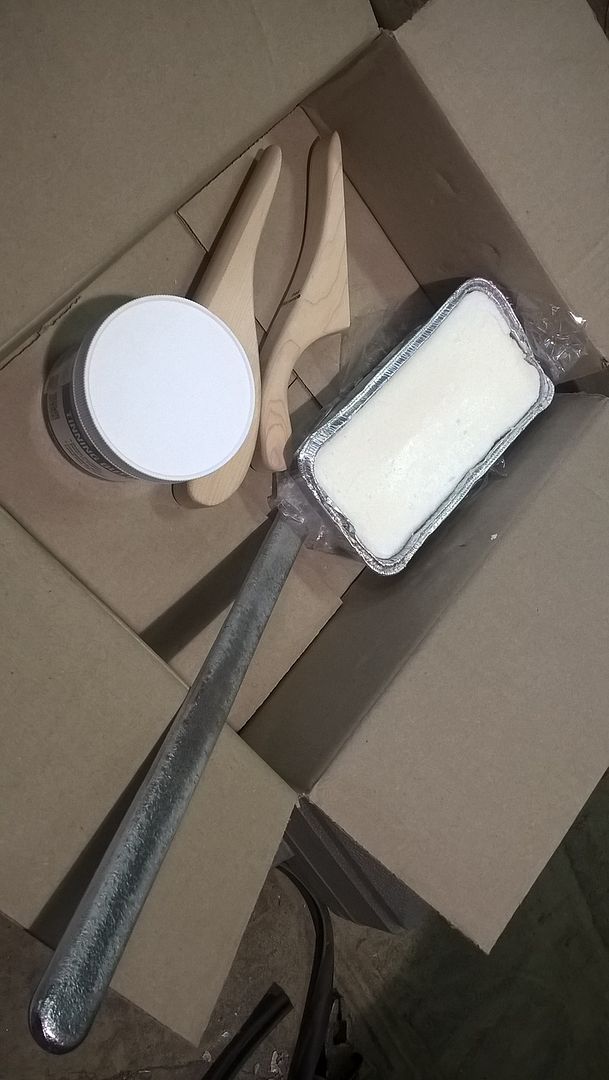

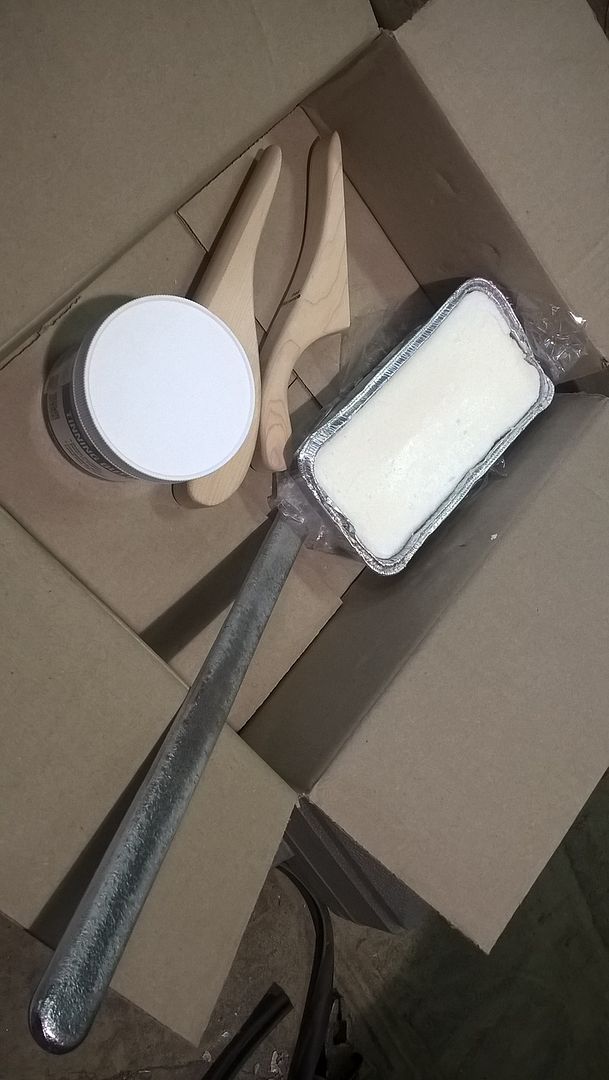

Well today was exiting and also a major challenge, I had a go at lead loading or swiping as the old timers called it. I bought a kit from eastwood products that supplies all that's needed for the job.

The first step is to clean everything to shiny bare metal

Then use a product called tinning butter, this must be done otherwise the lead wont stick.

Once the tinning is done the lead must be loaded, this is a hard job I had a lot fall on the floor.

The lead once on is not so hard to paddle around.

Filed, sanded then primed.

To be honest it didn't turn out to bad there is still some slight imperfections that will be filled with the surfacer primer that I intend using later on but with a bit more practice I think I can get it better, not a job I would enjoy on a Friday arvo before knock off ! Have to take my hat off to the people who put these cars together so long ago.

I have seven more joints to go, its going to be a long week !!

Regards Greg

Re: Chev EK

Posted: Sat Apr 02, 2016 10:38 pm

by In the Shed

Nice work Greg,

What is the material in the rectangular alumin tray? Also what were you using to warm the body/lead up to allow you to work it?

Regards

Stephen

Re: Chev EK

Posted: Sun Apr 03, 2016 2:17 am

by EK283

Hi Stephen,

The material in the aluminium tray is wax, it goes on the paddles to help smooth the lead without it picking up and dragging.

I used a propane torch that I bought at Bunnings, they are refillable / disposable yellow in colour.

Regards Greg

Re: Chev EK

Posted: Sun Apr 03, 2016 4:29 am

by Trev

Nice job Greg, I did that in a car restoration tafe coarse years ago, good to know how it's done.

Re: Chev EK

Posted: Sun Apr 03, 2016 3:13 pm

by parisian62

Top stuff Greg.

Re: Chev EK

Posted: Sun Apr 03, 2016 10:26 pm

by Devilrod

That's next level dedication to a rebuild, looks good.

Re: Chev EK

Posted: Mon Apr 04, 2016 10:10 pm

by In the Shed

Thanks Greg, appreciate your experience in something which is probably not done that often now days.

Regards

Stephen

Re: Chev EK

Posted: Tue Apr 05, 2016 9:48 am

by ek amigo

Good to see that old school stuff , I worked for the PMG back in the day and we wiped all the Lead sheathed cable joints , a favourite to use as a wiping pad was felt , usually from an old hat , and from memory the flux was called stearine or whale sperm .

Re: Chev EK

Posted: Wed Apr 06, 2016 12:21 am

by mph

NIce work mate ,looks a treat

Re: Chev EK

Posted: Sun Apr 10, 2016 10:35 am

by toey1977

good job. I don't want to sound like a stick in the mud pain in the arse but be careful of the fumes mate. in the panel trade now technically they made lead filling illegal for the same reasons they no longer make lead based paints. even more stupid is I had to learn it at trade school and then was told we cant do it at work for health and safety reasons of lead poisoning. so keep a respirator on. keep that metal clean a nicely fluxed worst thing of lead filling is sometimes the edges of the lead can lift so if it peels when filling clean and re-flux and go again. I do love the fact that you have replaced the lead in the join.

Re: Chev EK

Posted: Thu Apr 28, 2016 9:28 pm

by EK283

toey1977 wrote:good job. I don't want to sound like a stick in the mud pain in the arse but be careful of the fumes mate. in the panel trade now technically they made lead filling illegal for the same reasons they no longer make lead based paints. even more stupid is I had to learn it at trade school and then was told we cant do it at work for health and safety reasons of lead poisoning. so keep a respirator on. keep that metal clean a nicely fluxed worst thing of lead filling is sometimes the edges of the lead can lift so if it peels when filling clean and re-flux and go again. I do love the fact that you have replaced the lead in the join.

All good mate nothing but the best mask and ventilation I've even got lead cleaning wipes !

Farted around for the last couple of weekends making up some caltrac type traction rods.

I am a bit worried about the ground clearance, can anybody tell me what the distance is between the rear of the sill to the ground (in front of the rear wheel) measurement wise for stock or lowered please.

Regards Greg

Re: Chev EK

Posted: Fri Apr 29, 2016 12:06 pm

by FireKraka

Hi Greg

I know that when I had my FC Sedan engineered he said that the minimum ground clearance is 100mm from any point under the car whatever is the lowest to the ground.

Because I am running lowering blocks I the back he measured from the bottom of the shackle to the ground and I just cleared.

Hope this helps maybe doesn't answer your question but the I interpret it, it doesn't matter whatever height other parts are from the ground.

Regards

Neil H

Re: Chev EK

Posted: Fri Apr 29, 2016 1:00 pm

by Harv

G'day Greg,

The spec from NCOP (2.4.2 Ground Clearance and Running Clearance) is:

Ground clearance of a vehicle means the minimum distance to the ground from a point on the underside of the vehicle, except a point on a tyre, wheel, wheel-hub, brake backing plate or

flexible mudguard or mudflap of the vehicle. Running clearance of a vehicle means the distance from the surface on which an unladen vehicle is standing to the lowest point on the vehicle excluding unsprung mass.

All other motor vehicles with more than 3 wheels must have a ground clearance of:

at least 100mm at any point within 1 metre of an axle; and

at least one-thirtieth of the distance between the centres of adjacent axles at the midpoint between them; and

at any other point — at least the distance that allows the vehicle to pass over a peak in the road with a gradient on either side of 1:15, if the wheels of one axle of the vehicle are on the slope on

one side of the peak and the wheels of the next axle are on the slope on the other side.

If someone doesn't chime in before then, I can measure the standard FB clearance for you on Tuesday.

Cheers,

Harv