Dragway Wheels - wheel arch lip roller needed.

Re: Dragway Wheels - wheel arch lip roller needed.

Rosco I have Dragways and was also looking at rolling.

Much quicker and I'm concerned about narrower tracking on the rear end.

I don't want to try myself but finding a professional is difficult

Anyone know a good one on the Northside of Brisbane ?

Much quicker and I'm concerned about narrower tracking on the rear end.

I don't want to try myself but finding a professional is difficult

Anyone know a good one on the Northside of Brisbane ?

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: Dragway Wheels - wheel arch lip roller needed.

Wayne Chambers

President

FB EK Holden Car Club of N.S.W

President

FB EK Holden Car Club of N.S.W

Re: Dragway Wheels - wheel arch lip roller needed.

Still working/planning this out.

Wayne - the wheels you have are the "classic" - they have a chunkier spoke and require the rim to be fitted much further out.

I know people do run these wheels - Sam Crupi has them on his wagon and that is dropped quite a bit.

I took a peek under his guards and he has the lips rolled - just the lips.

I must ask him what diff housing he is running - I will have trouble understanding how he did it if it is FB/EK.

The wheels I have are the "revised" version - it has narrower spokes. The rims are exactly the same - but they are set further back towards the centre of the car.

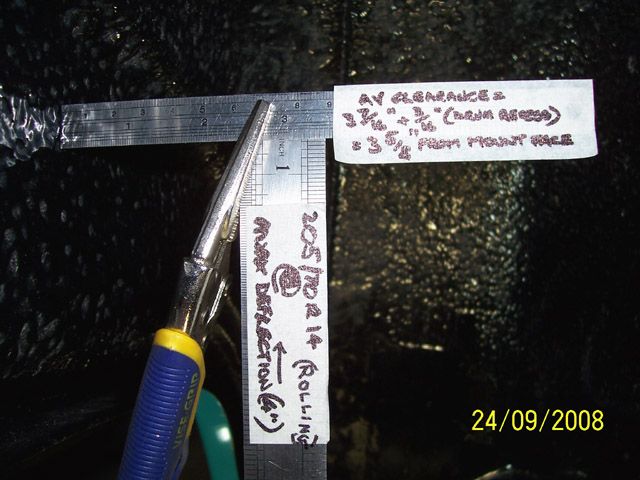

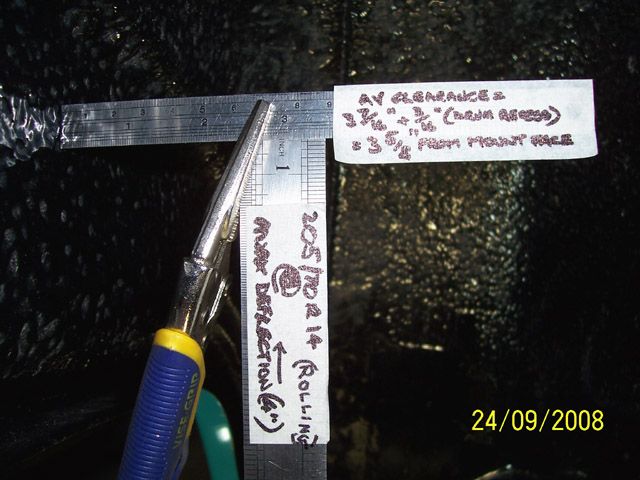

I chose the 14" x 7" with a 3.5" distance from the brake drum mounting face - because all those numbers went into each other perfectly.

The 3.5" is the least that can be assembled - the 14's I wanted because of the taller tyre rolling diameter and the 7's to get the tyre to "spread" across the wheel and reduce as much tyrewall bulge as possible.

I have 205/70's Goodyear GT-3's on these wheels - there is a very "kind" taper from the upper wall of the tyre to the tread.

Pic -

I worked very hard with Ray Dunn out at Dragway in Kinglake West (actually Pheasants Creek) - who did the machining of the alloy centre and fitted the rims to them.

He gave me as much as he could - machined down the alloy to the point that he would not permit any further reduction - and fitted them into the rims at the very extreme where the edge of the spoke was at the very start of the rim curve.... you simply can't get Dragways to sit any further in from under the outer lip of he guard.

Even with all these arrangements done - and the suspension wound up tight (without air shockers - which I do not like) - they scrub ever so slightly on big dips in the road at higher speeds - this is with Koni adjustable shock absorbers wound up to within one turn of maximum flow - I won't go any further than this for it does nothing more to restrict the upwards stroke - just makes the downward stroke slower.

Now, the next bit - rolling the guards..

It's not as simple as first believed. I took a long look at the lips of the guards again yesterday. Yes, you can roll up the very lip - but there is a double skin - and it is set back quite a distance from the outline of the body. This second skin is the luggage compartment wall in the cavity forward of the bootlid frame... from the side of the rear seat.

Rolling the lips might give nearly 1/2" clearance - but only a benefit of 1" lift until the tyre reaches this second skin - so, if you believe you are going to be able to drop the body to the floor with Dragways on - I'd be very interested to learn how this is accomplished without seriously breaking into both the arches and that second skin...

pix-

When we come to the front - it's not the outer rim which is the issue - but the inner.

Again, same wheels - 14 x 7 with the rim as far out as possible - the 7" rim "just" clears both the tie rod and the upper ball joint.

I ended up fitting 2 LU-1 spacers to the hubs - that gave me the added 3.5 mm of clearance from both..

The following pix were taken without the spacers - the rim "just" rubbed on the body flange of the upper ball joint with the suspension fully relaxed... as in the first pic. Second pic is with the suspension at mid point.

Spacers took care of all of the front clearance issues with 7" wide rims.

Pix -

Finny, we will finally meet up at HB - been looking forward to this for some time.

As for finding a competent person to roll the arches - I'd want some guarantee that they have done one of these old buses previously with successful results before engaging them to perform the work.... there is an awful lot of strength in there if the metal is sound - unlike most modern vehicles where you could probably achieve this with just a pair of Stilson's....

Wayne, on a closing note - to me, these Dragways (especially the ones you have fitted) "are" the sports wheels for these old cars... I'm not in love with modern wheels - and totally "over" the "Indy" wheels - they were all the rage back in the '70's.

If you take a peek at the edge of the outer rim - it sits very well under the arches - the distance from the mounting face of the brake drum is more than 1" inwards of our wheels... they became very popular very quickly, and I did not ever think that they belonged on old Holdens.... my opinion, you understand...

frats,

Rosco

Wayne - the wheels you have are the "classic" - they have a chunkier spoke and require the rim to be fitted much further out.

I know people do run these wheels - Sam Crupi has them on his wagon and that is dropped quite a bit.

I took a peek under his guards and he has the lips rolled - just the lips.

I must ask him what diff housing he is running - I will have trouble understanding how he did it if it is FB/EK.

The wheels I have are the "revised" version - it has narrower spokes. The rims are exactly the same - but they are set further back towards the centre of the car.

I chose the 14" x 7" with a 3.5" distance from the brake drum mounting face - because all those numbers went into each other perfectly.

The 3.5" is the least that can be assembled - the 14's I wanted because of the taller tyre rolling diameter and the 7's to get the tyre to "spread" across the wheel and reduce as much tyrewall bulge as possible.

I have 205/70's Goodyear GT-3's on these wheels - there is a very "kind" taper from the upper wall of the tyre to the tread.

Pic -

I worked very hard with Ray Dunn out at Dragway in Kinglake West (actually Pheasants Creek) - who did the machining of the alloy centre and fitted the rims to them.

He gave me as much as he could - machined down the alloy to the point that he would not permit any further reduction - and fitted them into the rims at the very extreme where the edge of the spoke was at the very start of the rim curve.... you simply can't get Dragways to sit any further in from under the outer lip of he guard.

Even with all these arrangements done - and the suspension wound up tight (without air shockers - which I do not like) - they scrub ever so slightly on big dips in the road at higher speeds - this is with Koni adjustable shock absorbers wound up to within one turn of maximum flow - I won't go any further than this for it does nothing more to restrict the upwards stroke - just makes the downward stroke slower.

Now, the next bit - rolling the guards..

It's not as simple as first believed. I took a long look at the lips of the guards again yesterday. Yes, you can roll up the very lip - but there is a double skin - and it is set back quite a distance from the outline of the body. This second skin is the luggage compartment wall in the cavity forward of the bootlid frame... from the side of the rear seat.

Rolling the lips might give nearly 1/2" clearance - but only a benefit of 1" lift until the tyre reaches this second skin - so, if you believe you are going to be able to drop the body to the floor with Dragways on - I'd be very interested to learn how this is accomplished without seriously breaking into both the arches and that second skin...

pix-

When we come to the front - it's not the outer rim which is the issue - but the inner.

Again, same wheels - 14 x 7 with the rim as far out as possible - the 7" rim "just" clears both the tie rod and the upper ball joint.

I ended up fitting 2 LU-1 spacers to the hubs - that gave me the added 3.5 mm of clearance from both..

The following pix were taken without the spacers - the rim "just" rubbed on the body flange of the upper ball joint with the suspension fully relaxed... as in the first pic. Second pic is with the suspension at mid point.

Spacers took care of all of the front clearance issues with 7" wide rims.

Pix -

Finny, we will finally meet up at HB - been looking forward to this for some time.

As for finding a competent person to roll the arches - I'd want some guarantee that they have done one of these old buses previously with successful results before engaging them to perform the work.... there is an awful lot of strength in there if the metal is sound - unlike most modern vehicles where you could probably achieve this with just a pair of Stilson's....

Wayne, on a closing note - to me, these Dragways (especially the ones you have fitted) "are" the sports wheels for these old cars... I'm not in love with modern wheels - and totally "over" the "Indy" wheels - they were all the rage back in the '70's.

If you take a peek at the edge of the outer rim - it sits very well under the arches - the distance from the mounting face of the brake drum is more than 1" inwards of our wheels... they became very popular very quickly, and I did not ever think that they belonged on old Holdens.... my opinion, you understand...

frats,

Rosco

Re: Dragway Wheels - wheel arch lip roller needed.

Anyone got a pic of "Sam Crupi" car with the dragways?...

Wayne Chambers

President

FB EK Holden Car Club of N.S.W

President

FB EK Holden Car Club of N.S.W

Re: Dragway Wheels - wheel arch lip roller needed.

I can tell you now it'll be a Torana Diff. Sadly if that's the limit machining wise Rosco you'll never get them to fit right short of narrowing the diff. All the backspacing is going to waste purely because the wheels don't have the offset the way its really needed. As you said not many options when it comes to what looks right, but something that really needs to be taken into account in a build.rosco wrote:Still working/planning this out.

Wayne - the wheels you have are the "classic" - they have a chunkier spoke and require the rim to be fitted much further out.

I know people do run these wheels - Sam Crupi has them on his wagon and that is dropped quite a bit.

I took a peek under his guards and he has the lips rolled - just the lips.

I must ask him what diff housing he is running - I will have trouble understanding how he did it if it is FB/EK.

As for yours Wayne you are in the same boat. Although yours also looks like rim width is against you too. Back in the early 90's I bought as set of the much maligned (by Rosco

Big Nev has rims with a similar look to Dragway and doesn't seem to have clearance issues? whats he running?

Speed and Style........... One day I'll get the speed bit.

Re: Dragway Wheels - wheel arch lip roller needed.

Speed and Style........... One day I'll get the speed bit.

Re: Dragway Wheels - wheel arch lip roller needed.

That yellow FB wagon makes me all moist around the gusset ........

I started with nothing and still have most of it left.

Foundation member #61 of FB/EK Holden club of W.A.

Foundation member #61 of FB/EK Holden club of W.A.

Re: Dragway Wheels - wheel arch lip roller needed.

I'm all 6's and 7's over this....

Wayne Chambers

President

FB EK Holden Car Club of N.S.W

President

FB EK Holden Car Club of N.S.W

Re: Dragway Wheels - wheel arch lip roller needed.

its wheely confusing , we just seem to be going round and round about this subject - it makes me feel a bit deflated

I started with nothing and still have most of it left.

Foundation member #61 of FB/EK Holden club of W.A.

Foundation member #61 of FB/EK Holden club of W.A.

Re: Dragway Wheels - wheel arch lip roller needed.

Yes you really seem under the pump and don't seem be getting any traction, maybe you should take a brake before you get driven up the wall.

Glenn

Re: Dragway Wheels - wheel arch lip roller needed.

Hey Rosco, looking forward to meeting you also.

I have a similar post related to wheels.

After looking at the tyres today, I did a ring around and I'm thinking that changing the tyres may solve the issue.

Currently mine at 205 60 r13 but if I fit 185 80 that will reduce the width, and may be enough to stop it hitting.

May still need rolling but it would be a lot less.

It will cost me about $200 for 2 tyres to test the theory, unless someone else is already running those tyres.

I have a similar post related to wheels.

After looking at the tyres today, I did a ring around and I'm thinking that changing the tyres may solve the issue.

Currently mine at 205 60 r13 but if I fit 185 80 that will reduce the width, and may be enough to stop it hitting.

May still need rolling but it would be a lot less.

It will cost me about $200 for 2 tyres to test the theory, unless someone else is already running those tyres.

IT's LIKE WATCHING DRUNK MONKEYS TRYING TO HUMP A FOOTBALL.

Re: Dragway Wheels - wheel arch lip roller needed.

If your at the Nats many of us run 185 80 R13 someone one will let you try, leave it till then,,

I'm stuck with 205 60 R13 as well mate..

I'm stuck with 205 60 R13 as well mate..

Wayne Chambers

President

FB EK Holden Car Club of N.S.W

President

FB EK Holden Car Club of N.S.W

Re: Dragway Wheels - wheel arch lip roller needed.

Thanks Brett - I am do my very best to avoid that Torana diff - think everyone can appreciate this.

If you knew just how "little" these tyres scrub (after four runs now, including some really corrugated and winding/rough dirt road - there's almost nothing marked on the walls... you really have to look at the smooth surface of the tyre name to see anything).

We're loading up the car tomorrow with what we'll do the run to HB with.. and take it on a 20 mile run where we've heard the couple of rubs before.. if it's no worse - I'll run HB and back as is....

To completely avoid any scrubbing - I need about 1/4" at the lip of the arch... and only a length of about 4".

To answer the request to see Sam's car - it's in one posted above.... the pink wagon with Dragways on it.

Both this one and it's brother - the light blue/grey are both in "sports" category - if I am not mistaken, they are supposed to have EK rear ends....

Finny - yes, be great to catch up with you... we've got a bit of ground to cover - looking forward to looking over your car.

So, guess I'll have to make a report tomorrow night.

I'd love to simply be able to bend up the very lip of the arch to get that 1/4".... any suggestions?

frats,

Rosco

If you knew just how "little" these tyres scrub (after four runs now, including some really corrugated and winding/rough dirt road - there's almost nothing marked on the walls... you really have to look at the smooth surface of the tyre name to see anything).

We're loading up the car tomorrow with what we'll do the run to HB with.. and take it on a 20 mile run where we've heard the couple of rubs before.. if it's no worse - I'll run HB and back as is....

To completely avoid any scrubbing - I need about 1/4" at the lip of the arch... and only a length of about 4".

To answer the request to see Sam's car - it's in one posted above.... the pink wagon with Dragways on it.

Both this one and it's brother - the light blue/grey are both in "sports" category - if I am not mistaken, they are supposed to have EK rear ends....

Finny - yes, be great to catch up with you... we've got a bit of ground to cover - looking forward to looking over your car.

So, guess I'll have to make a report tomorrow night.

I'd love to simply be able to bend up the very lip of the arch to get that 1/4".... any suggestions?

frats,

Rosco

Re: Dragway Wheels - wheel arch lip roller needed.

Wooden baseball bat and use the wheel to help roll it in jus enough to clear? Might take a bit but it should work. Roll and lever as you go?

Speed and Style........... One day I'll get the speed bit.

Re: Dragway Wheels - wheel arch lip roller needed.

Thanks Brett,

my "plan" was to fabricate a slotted tool from stock hardened steel...

I was going to cut the hooked end off a jemmy bar and slot it, round the head on the inboard working end and "lever" the edge of the lip using the outboard side of the slit.

Of course, I'd have a strip of rubber on both sides to help prevent edging... slow process... I need to work only a section of about 4" long - and only need 1/4" further clearance...

I could run as is - but I'd be happier without the very occasional light rub as we go through a big dip at speed.... so close, just so close to being issue free.... 1/4" from destiny....

"if" I go ahead with my plan - any sign that it's not "working" - will be the end of ever trying this again... I might only end up with angling the lip up by 15 degrees - that would be enough.. it's absolutely fine on cornering... braking or anything else - it's just a non-explained "dip" - which results in the light rub we hear.... none of the paint on the inside of the lip has been worn off yet... think you can appreciate just how little I need to get this free of rubbing....

Will report tomorrow.

frats,

Rosco

my "plan" was to fabricate a slotted tool from stock hardened steel...

I was going to cut the hooked end off a jemmy bar and slot it, round the head on the inboard working end and "lever" the edge of the lip using the outboard side of the slit.

Of course, I'd have a strip of rubber on both sides to help prevent edging... slow process... I need to work only a section of about 4" long - and only need 1/4" further clearance...

I could run as is - but I'd be happier without the very occasional light rub as we go through a big dip at speed.... so close, just so close to being issue free.... 1/4" from destiny....

"if" I go ahead with my plan - any sign that it's not "working" - will be the end of ever trying this again... I might only end up with angling the lip up by 15 degrees - that would be enough.. it's absolutely fine on cornering... braking or anything else - it's just a non-explained "dip" - which results in the light rub we hear.... none of the paint on the inside of the lip has been worn off yet... think you can appreciate just how little I need to get this free of rubbing....

Will report tomorrow.

frats,

Rosco